Introduction to technological design and off-design simulation models

In Thermoptim versions 2.5 and 2.6, the models implemented have limitations. To overcome them, we were led to distinguish two levels in the models (their name was chosen to be as clear as possible, but it is not usual):

Phenomenological models, the only ones used in Thermoptim versions 2.5 and 2.6, provide access to the calculation of thermodynamic cycles, irrespective of the choice of a particular component technology;

Technological design and off-design simulation models not only provide the same results as the previous ones, but in addition allow the user to geometrically size the various components and, once the technological design is achieved, to study the behavior of the system outside the operating conditions for which it has been designed. These models are implemented in Thermoptim versions 2.7 and 2.8.

Off-design analysis of energy systems poses many problems much more difficult to resolve than those we faced when we merely studied thermodynamic cycles in purely phenomenological terms at rated point, independently of technology choices.

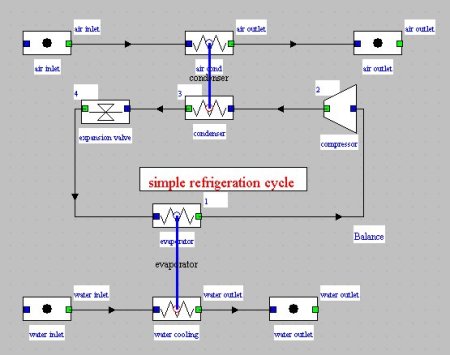

Let us consider for example a simple refrigeration cycle, very easily modeled with Thermoptim phenomenological version (Figure below). To set up such a model, we set the values of flow rate, evaporation and condensation pressures as well as compressor isentropic efficiency, but we need specify neither the exchange surfaces brought into play, nor the type of compressor used (piston, scroll, centrifugal etc.). Thermoptim then allows us to calculate the thermodynamic state of all points of the cycle and the energies involved.

For the model to make an actual technological design, we must also specify as precisely as possible the type and physical dimensions of the various components used. In the case of a refrigeration machine, we have to choose a type of compressor, for example in a list of devices available on the market. If it is a displacement machine, we should at least provide its swept volume and the volumetric and isentropic efficiency laws depending on compression ratio and rotation speed. For heat exchangers, we must first choose the flow pattern (plate, shell and tube. etc.) and then calculate the exchange surfaces, which involves determining internal heat exchange coefficients, and therefore dimensionless numbers governing thermal transfer between the fluids involved and the walls (Reynolds, Prandtl and Nusselt numbers).

By making these technology choices, we indirectly determine some parameters on which we could previously play freely. For example, in the case of a displacement compressor, flow is not necessarily exactly the one that was desired: it depends on the swept volume, compression ratio, suction specific volume, volumetric efficiency, rotation speed etc.

To realistically simulate the system in off-design mode, we must be able not only to make the technological design of each component, but also to characterize the interactions between components due to their adaptation to new operating conditions.

Computer implementation, documentation

The computer solution was to combine the use of:

Technological design classes

A driver which takes over the automatic recalculation engine to perform off-design behavior studies

Technological design classes supplement the core allowing the consideration of equations which are specific of the technological choices made, such as calculating the heat transfer coefficient U of a heat exchanger, or a compressor's volumetric and isentropic efficiencies.

The driver ensures the systemic coordination of the various component calculations.

It looks for a set of coupling variables consistent with the physical and technological problem posed, solves the system of equations that connects them, and thus makes it possible to modify the setting of the Thermoptim project

When performing off-design simulations, each setting leads to a new result, which can be saved in a specific project file. This generates a set of files with the same structure which we can exploit thanks to the post-processing Excel macro .

The implementations of these new Thermoptim features are mostly made in the form of external classes, which provides great flexibility for users to customize them.

The classic phenomenological Thermoptim version remains unchanged: it is only completed by a software layer to take into account the technological design and off-design models.

Note, however, that all the setting options available in the usual Thermoptim screens (phenomenological) are not necessarily valid in off-design mode, and it is therefore important to include in the external classes that we develop, tests to verify their compliance with the assumptions of the models selected.

Given the extent of the field corresponding to these problems, we cannot in any way claim to provide them with comprehensive answers: we limit our ambition to illustrate on a few relatively simple examples, the potential of drivers and technological design and off-design tools.

To this end, the reference manual of the software was completed by a fourth volume dedicated to these new developments .

In this portal you will find several pages devoted to these developments, including the one that presents the problems posed by technological design and off-design operation , and another that provides various implementation examples.

We refer you also to Part 5 of the first edition of the book Energy Systems published in 2011, if you are interested in more explanations on this, including the thermodynamic models considered.

Remark

As mentioned above, the versions of Thermoptim that allow one to make technological design and off-design studies are versions 2.7 and 2.8.