General methodological approach

The approach proposed in this book is based on the observation that thermodynamics is much simpler in the qualitative than quantitative terms.

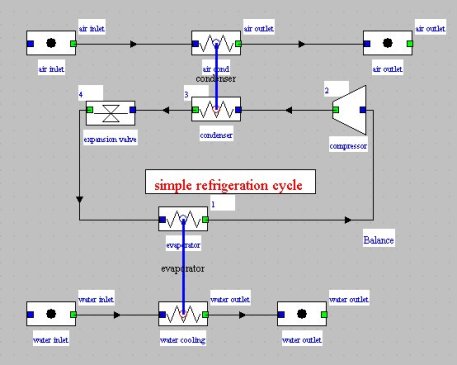

Energy technologies being assemblies of components through which flow thermodynamic fluids which undergo various processes, we greatly simplify things if we adopt a dual approach, starting by separating the representation of the overall system, usually quite simple, from the study of its components taken individually.

The overall representation is very useful at the qualitative level: it is visual and helps us to understand the role played by each component in the complete system. When learning the subject, it is essential to fully assimilate the design principles of these technologies. Once one has in mind the internal structure of an engine or refrigerator, the study of the behavior of one of its components is made easier because we understand its place in the whole and how it contributes to the overall performance.

If one has a proper graphical environment such as the Thermoptim diagram editor, the internal structure of the system can be described very easily. This gives a qualitative representation, very meaningful for the engineer, which can be quantified by setting the thermodynamic properties of the different components and then calculating them. This qualitative representation has furthermore the distinction of being largely independent of assumptions that are adopted for the calculation of the various components: it is an invariant of the system. Thus, a given system architecture can be calculated with various component models.

Complementarity of analytical and systems approaches

This double modeling approach involves two approaches often presented as exclusive but which are in this case complementary and mutually enriching:

the analytical approach used to represent each component by a number of characteristic parameters, coupling variables and a set of appropriate equations;

the systems approach as regards the definition of the internal architecture of the system (choice of components, description of their relationships) ;

Not only does such an approach significantly simplify the modeling process and facilitate subsequent use and maintenance of the model, but mostly it secures its construction by automating the establishment of linkages between the various component elements and ensuring consistency. This point is especially important when the system under study comprises a large number of components.

Two methodological notes on the model have been written to your attention:

The first one, entitled Numerical models and modeling environments: tools to effectively mobilize the scientific knowledge , provides a broad panorama of how an engineer may use modeling;

The second one, entitled Model construction and verification methodology , is especially dedicated to the modeling of energy systems with Thermoptim.

This way of working is increasingly becoming the only means of focusing efforts on the study of innovative cycles, which is now a field of research both exciting and essential for the future.

The many interesting ideas that have been proposed recently, for example to develop cycles without CO2 emissions, are there to bear witness to the fruitfulness of this area of investigation, which it is essential to educate our students.

Systems-analysis of energy technologies

The systems analysis of an energy technology can be broken down into four basic steps:

analysis of the structure (or architecture) of the technology in question, which highlights its main functional elements and their connections. This task can prove trickier than it seems because some components sometimes provide different functions in different phases of operation. It is facilitated if one has a basis of well chosen primitives. The structure of the system thus demonstrated is an invariant almost independent of the fineness retained for the modeling of components;

for each element, identification of the thermodynamic fluids that come into play: for example, the fluid compressed in a gas turbine is air, which burns a fuel in the combustion chamber to form burnt gases themselves expanded in the turbine. In this case it is necessary to consider three thermodynamic fluids: in the compressor, air which may possibly be moist, in the combustion chamber, air, fuel, and burnt gases, and in the turbine the exhaust gases;

for each element, accurate determination of processes undergone by the various fluids identified, and calculation of their changes. The degree of fineness of modeling depends on the desired accuracy and available data. In this work, we will only quantitatively model overall component behavior, using parameters to characterize it (characteristics), and limit to qualitative considerations the analyses of the specifics of what happens internally;

establishing the overall model of the system considered by assembly of the different types of functional elements. When the previous steps have been taken with care, it is usually not of particular difficulty. At most we should take care to define the types of energy that come into play, to be sure to count them properly, particularly when one wishes to calculate a cycle effectiveness, which is often the case.

Once these steps are undertaken, all the elements are available to pass to the system optimization phase, which can be made on the one hand by making sensitivity studies around key design parameters, and on the other hand by using specialized tools.

Practical implementation

To implement the dual systems/analytical approach that we advocate, we must operate in two stages:

begin by building models of system components;

assemble them to create the model of the overall system.

The Thermoptim core was built to help represent the most common components: compressors, turbines, combustion chambers, expansion valves and heat exchangers. Their thermodynamic models being almost universally accepted, it was possible to program them once and for all.

The software includes a second family of components, which take the form of external Java classes. These components (e.g. solar collectors, cooling coils, cooling towers, fuel cells, chemical reactors etc.) are easily customizable by users, who thus have the opportunity to define themselves the phenomenological and behavior models they wish to retain.

The first step is essential and a prerequisite so that the systemic approach can be implemented. For a user, the problem is different depending on whether a realistic enough model is available or not in Thermoptim core or among external classes:

when all required components are already available, the modeling approach is essentially limited to the systemic phase: it consists of assembling models of pre-built components, and then set them;

when it is necessary to develop some component models, the external classes development environment allows one to create these models and make them compatible with the software.

Once the component models are available, building the model of a thermodynamic system with Thermoptim is very simple:

we first make a qualitative description by representing it graphically as a set of components connected by links representing the fluid pipes or heat exchangers;

the model defined is then quantified by setting the various primitive types that are involved, in order to calculate its performance, making use of the predefined templates.

The diagram editor allows for the qualitative stage: the user provides in a first step only the minimum information necessary for the logical definition of the project he builds (implicitly the types of components that he selects and explicitly their name and exit point and the substance associated with them, as well as the value of the flow through them). Then, when he interconnects these components, some of this information is automatically propagated from upstream to downstream (for example, the inlet point of the downstream component becomes the same as the one at the upstream component outlet). This small number of basic information provided to the graphical modeler corresponds to the systemic description of the technology studied.

When this step is complete, it becomes possible to transfer in the simulator the diagram components to create the primitive types required, with a default setting of their thermodynamic properties. Quantification of the desired model can then be made by refining this setting, each element of the simulator being easily displayed by double-clicking either on the corresponding component in the diagram editor, or on a table line of the main simulator project screen.

Once the element parameters are set and calculated, the results can be directly displayed in the diagram editor, which thus becomes a true synopsis of the installation, or plotted as a cycle in one interactive chart.