Thermoptim reference manual Volume 3

Table of contents

© R. GICQUEL 1997 - 2022. All Rights Reserved. This document may not be reproduced in part nor in whole without the author’s express written consent, except for the licensee’s personal use and solely in accordance with the contractual terms indicated in the software license agreement.

Information in this document is subject to change without notice and does not represent a commitment on the part of the author.

1 Foreword

Thermoptim documentation

Thermoptim documentation is comprised of several complementary parts:

- a short documentation named Quick Reference available through menu Help: it gives access to tab frames introducing the main concepts used

- a printable documentation, mainly as pdf files

- on line e-learning modules with sound tracks named Diapason

- guided explorations of Thermoptim models

The documentation available is presented in Volumes 1 and 2 of the reference manual.

This is the third volume. It is dedicated to the design of external classes. After a quick introduction to the extension mechanism that has been adopted, it explains how to use and program external classes, and introduces a freely distributed development environment.

2 Extension system for Thermoptim by adding external classes

One great advantage of Thermoptim is that its graphic environment can be used to visually build models for a large number of energy systems, from the simplest refrigerator to complex integrated gasification combined cycle electric power plants using several hundred elements.

Not only does this greatly simplify the modeling process and facilitate subsequent use and maintenance of the model, but it also makes the models more reliable. The connections between the different elements are made automatically, thus ensuring consistency.

Through version 1.4, only the components available in the Thermoptim primitive type set could be assembled in this manner, which limited the potential of the software. A number of users wished to be able to define their own elements and/or their own substances.

Thermoptim interface with external classes (Java code elements) provides the solution and facilitates the interoperability of the software with the outside world, especially with other applications developed using Java.

The benefits are two-fold:

- create Thermoptim extensions from common primitive type set, by adding external modules that define the elements that automatically appear on the screens in a seamless fashion. Thus users can add their own substances or components not available in the basic set.

- drive Thermoptim from another application, either to guide a user (smart tutorial) or to check the code (driver or regulation, access to thermodynamic libraries).

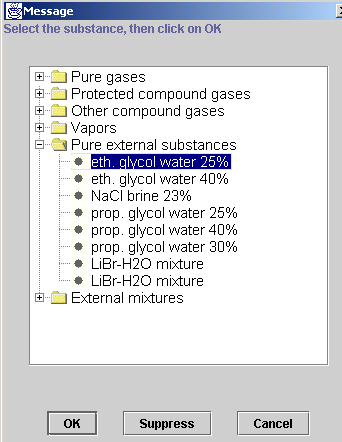

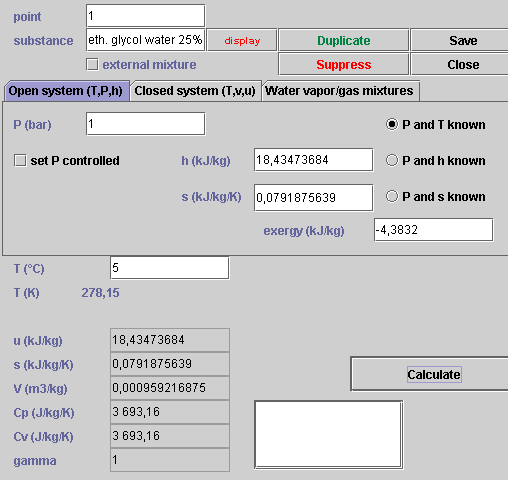

The previous and opposite figures show how the external substances are added to Thermoptim list of substances, and then replace an internal substance on the point screen. They are just as easy to use as if they were part of the software.

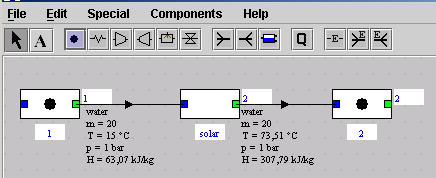

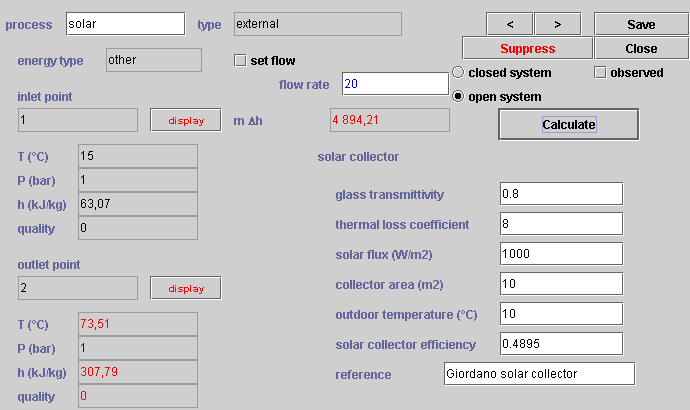

The figure opposite shows how an external component representing a solar collector appears in the diagram editor, and the figure below shows the screen of the corresponding process, composed partly of Thermoptim internal code and partly of external code (lower third on the right).

2.1 Software implementation

Practically speaking, adding a new external process is quite easy. Simply create a specific class, which inherits from the abstract parent class extThopt.ExtProcess. The interaction with Thermoptim is ensured on two levels:

by general methods for performing the required calculations;

by a JPanel that is built in to the external process screen. Thus, the class designer can create his own graphic interface, which is then inserted into the Thermoptim screen.

2.2 Programming issues

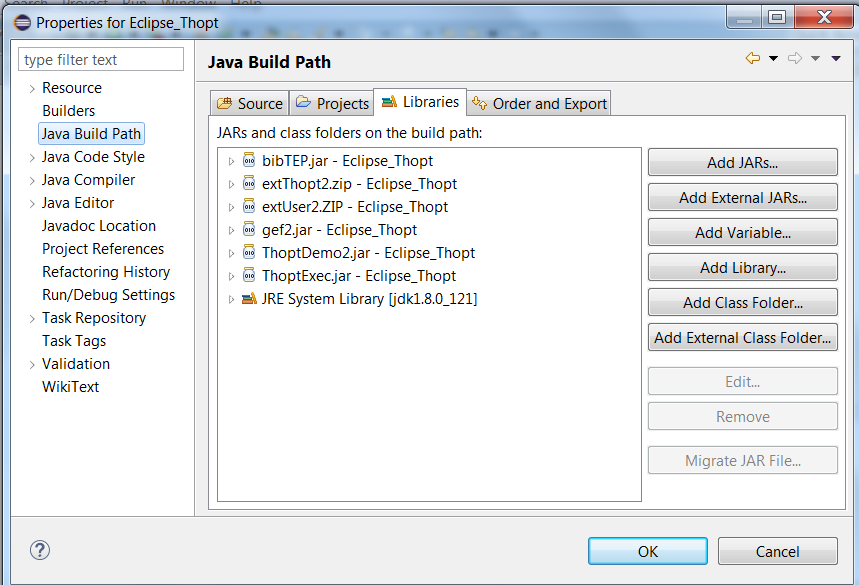

To protect the Thermoptim code, its classes are “obfuscated”, i.e. all of its elements are renamed, making it extremely difficult to decompile. However, this makes it impossible to access the Thermoptim content from the outside. The solution is not to obfuscate the methods that we want to be accessible. Thus there we must find a compromise between accessibility and code protection, which means providing as few accesses as possible. For the moment, only two Thermoptim packages out of five are partially accessible: rg.thopt and rg.corps. The first contains the simulator classes and the second the substance classes.

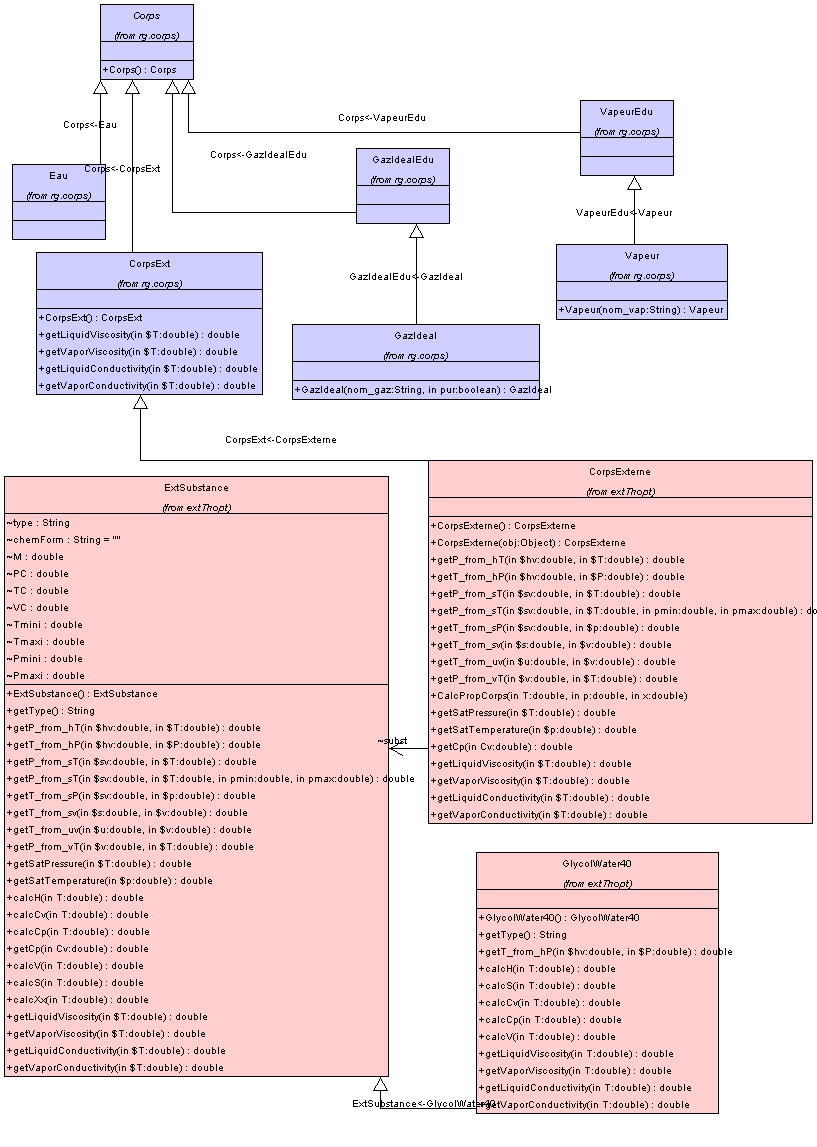

The solution consists of adding a non-obfuscated package (extThopt), in which there are classes (for example extThopt.CorpsExterne), recognized by Thermoptim, which are subclasses of Thermoptim classes, through interface classes (extThopt.CorpsExterne is a subclass of rg.corps.CorpsExt, which in turn is a subclass of rg.corps.Corps). These classes have methods that establish the correspondence with their obfuscated internal equivalent. We recommend that you refer to the API of the package extThopt to learn about the syntax and functions of all of the methods available. This API is part of the development environment of the external classes available (in the folder api_extThopt).

2.3 Using the external classes

In version 1.5, there are four types of external classes: substances, processes, dividers, and external nodes. The same principle applies to all: in the external package (extThopt), an input class is simply an extension of one of the Thermoptim classes (CorpsExterne for substances, TransfExterne for processes, etc.). All of the external overloaded Thermoptim methods are located in this class. ExtThopt simply acts as the input point in its package. Its role is to instantiate the various classes representing the elements added to Thermoptim and to interface with the software using overloaded methods.

External classes inherit from an abstract parent class. For example, ExtSubstance for substances, ExtProcess for components. In practice, the interaction with Thermoptim is ensured at one or two levels, depending:

- parent classes define all of the general methods useful for performing the required calculations

- with the exception of ExtSubstance, they also define a JPanel that is incorporated into the screen of the external component. In this way, the designer can create his own graphic interface, which then appears on the Thermoptim screen. The designer can define his own graphic elements (buttons, fields, labels, etc.) and process specific actions in his methods. For the components, two methods, saveCompParameters() and readCompParameters(String ligne_data), save the parameter settings in the Thermoptim project file, for use when the project is loaded.

In short, external classes, such as CorpsExterne or TransfExterne, inherit directly from Thermoptim classes and ensure the interface with the software. They call abstract classes, such as ExtSubstance or ExtProcess, whose subclasses may be freely designed by the users via interface methods and JPanel.

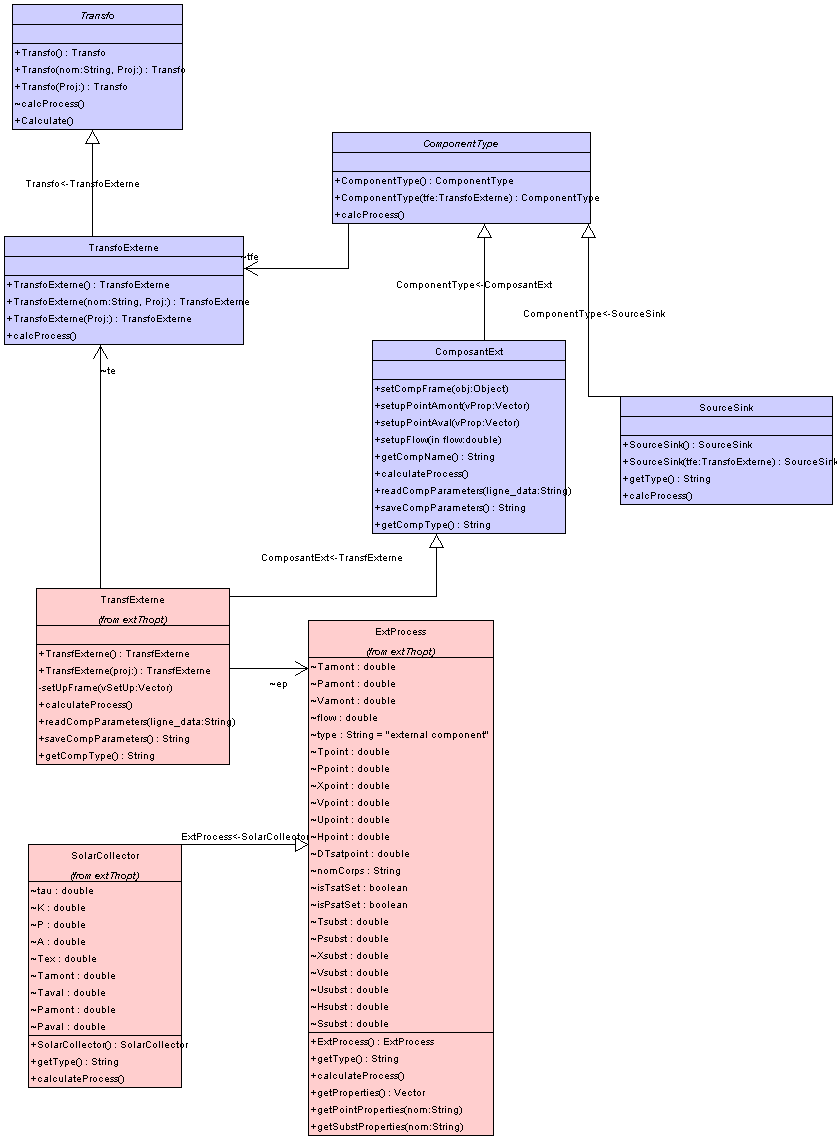

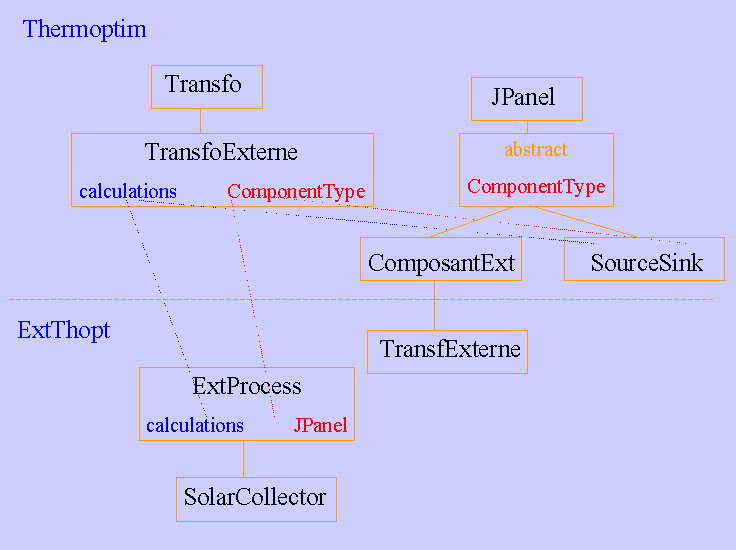

The diagram below illustrates the structure used for external processes. For substances, the diagram is the same, but simpler. Since there is no graphic interface, there is no need for the right-hand part of the diagram. People familiar with UML notation will find the class diagrams for external substances and processes in Appendix 5.

The top part of the diagram corresponds to classes present in Thermoptim basic set, and the lower part corresponds to the extThopt package that can be modified by the external class designer. SourceSink is a default implementation of ComponentType to be able to instantiate a TransfoExterne, even in the absence of external classes of this type, and SolarCollector and LiBrAbsorption are examples of external classes. The dotted blue and red lines symbolize the relays of the parts of the code relating to the calculations and the graphic interface, made from TransfoExterne to the other classes, either internal classes (SourceSink) or external classes (subclasses of ExtProcess).

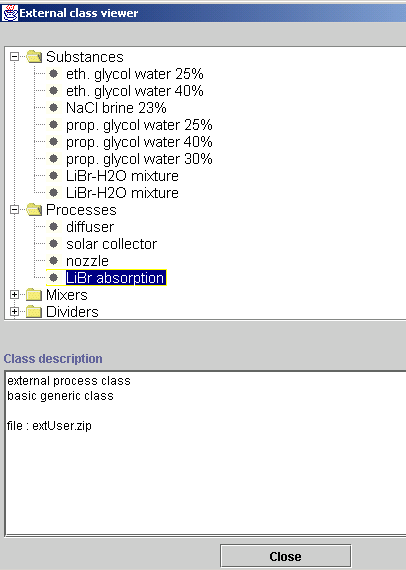

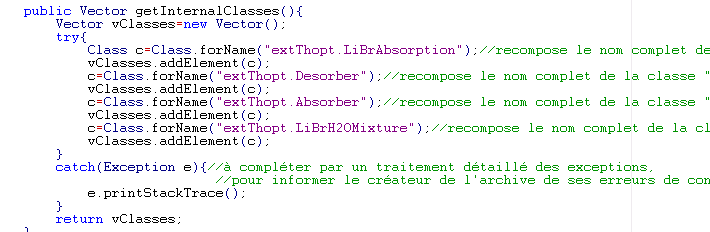

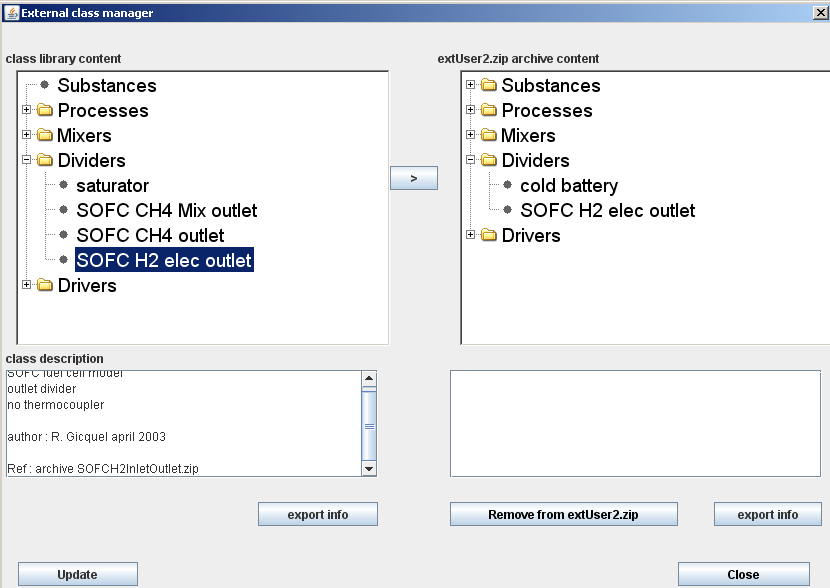

Thermoptim selects directly from the external classes as follows: When it is launched, the software analyzes the archives extThopt2.zip and extUser2.zip, which contain all of the external classes. It finds all of the classes added by default and by the users and sorts them by parent class, loads them in the various types of arrays, and adds the external elements to its own lists so that they are seamlessly accessible. Subsequently, if one of these elements is selected, Thermoptim sends its class to the appropriate constructor, which instantiates it. The line External Class Viewer in the Special menu shows the external classes available (see section 3.6).

Once an external component is instantiated, it is possible to change it by double-clicking on its type as it appears on the screen.

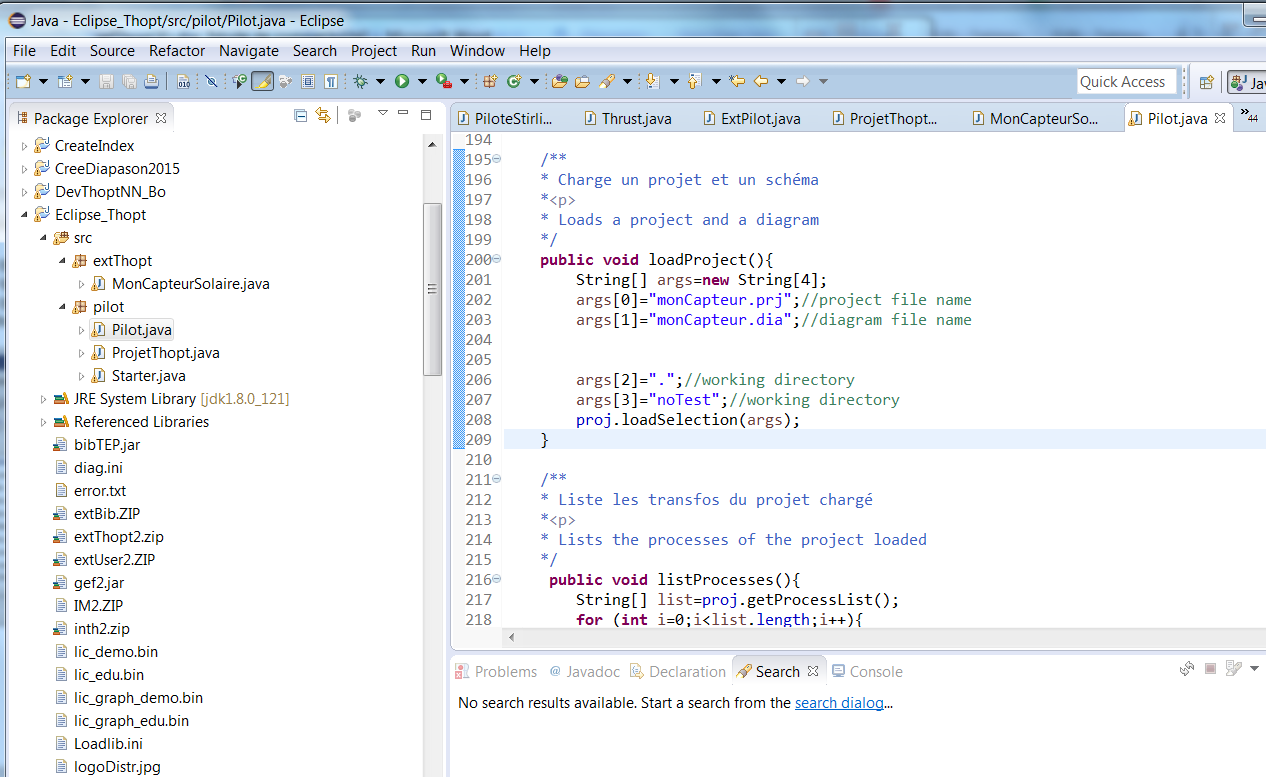

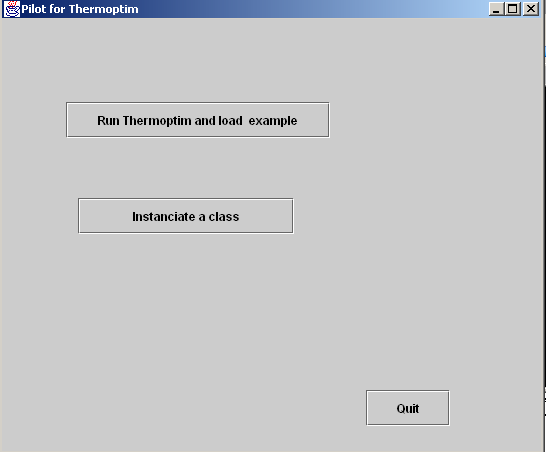

For now, there is no consistency test on the class names and element types, but this feature will be added shortly. For the development of external classes, an emulation system makes it possible to launch Thermoptim from an external application, and to dynamically load the classes under development, providing access to the debugging tools in the usual working environment (see section 6).

Moreover, the package extThopt includes a Util class that provides a number of utility methods for formatting numbers, reading them onscreen, saving and reading values, finding roots using the bisection method, etc. (see Appendix 3).

2.4 Three categories of interface methods

The classes used in Thermoptim, CorpsExterne, TransfExterne and the other, define the interface methods, which fall into three additional categories:

- Internal Thermoptim methods designed to be obfuscated

- Non-obfuscated internal methods that are directly used by the external classes: These methods are used to execute the Thermoptim methods with external parameter settings, and must not be overloaded. Their signature must be strictly respected: in particular, the structure of the Vectors of Objects used as arguments must correspond exactly to what Thermoptim expects, or a ClassCastException will be generated.

- External methods corresponding to Thermoptim obfuscated methods: These methods are used to execute the external methods from within Thermoptim, and must be overloaded.

The non-obfuscated methods falling into the last two categories are listed in Appendix 1, for all of the accessible classes. For more information, please see the html documentation for these classes provided in the folder api_Thermoptim.

2.5 Using external components

2.5.1 Viewing the available external classes

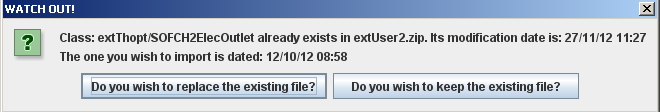

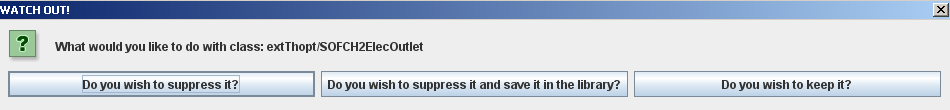

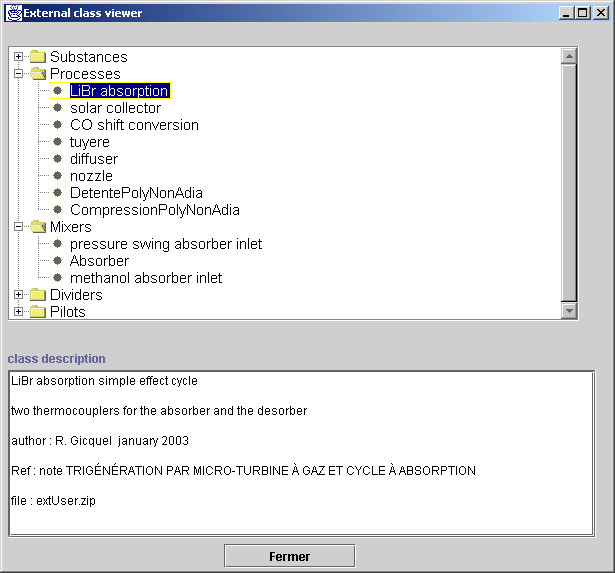

To help you use and manage the external classes, the line External Class Viewer from the Special menu displays all of the external classes available. They are sorted by type (substances, processes, mixers, dividers, drivers) with a short description of the class selected and where it comes from (extThopt2.zip and extUser2.zip archives as well as classes under development).

This screen can be consulted while you are developing your model.

2.5.2 Representation of an external component in the diagram editor

Specific icons were added to represent the external components (

for processes,

for mixers, and

for dividers). The external component is then selected when the simulator is updated from the diagram as indicated below.

2.5.3 Loading an external class

To load an external process (for an external node, the process is the same), you can either:

- from the simulator screen click on the column header of the process array, then choose External and finally select the type of external process you want from the list;

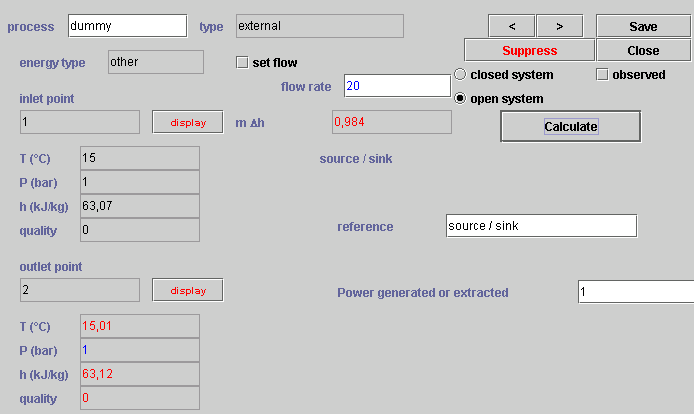

- Or, from the diagram editor, build the external component graphically then update the simulator from the diagram. In the case of an external process, by default it is a “heat source / sink” type, as shown in the screen opposite.

Once this default process is created, double click on the label “source / sink” to access the list of all external processes available. Choose the one you want and it will be loaded.

2.5.4 Thermocouplers

The thermocoupler system completes the heat exchanger system by allowing components other than exchange processes to connect to one or more exchange processes to represent a thermal coupling. This system does not encompass the exchanger system: two exchange processes cannot be connected by a thermocoupler.

This system has a number of benefits, because it can be used to represent many thermocouplers that do not constitute a heat exchange in the traditional sense, like for example cooling the walls of the combustion chamber of a reciprocating engine, cooled compression, and above all supply or removal of heat from the multi-functional external components.

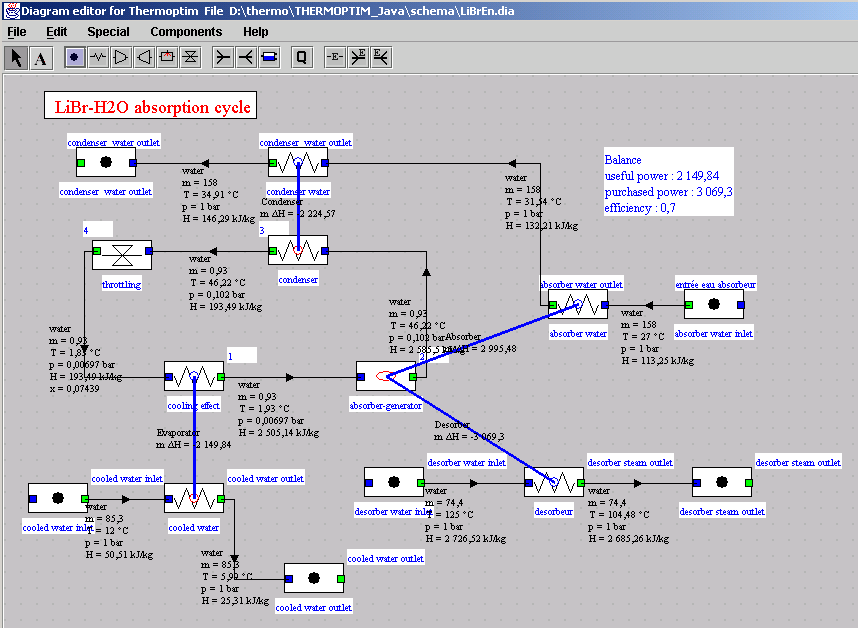

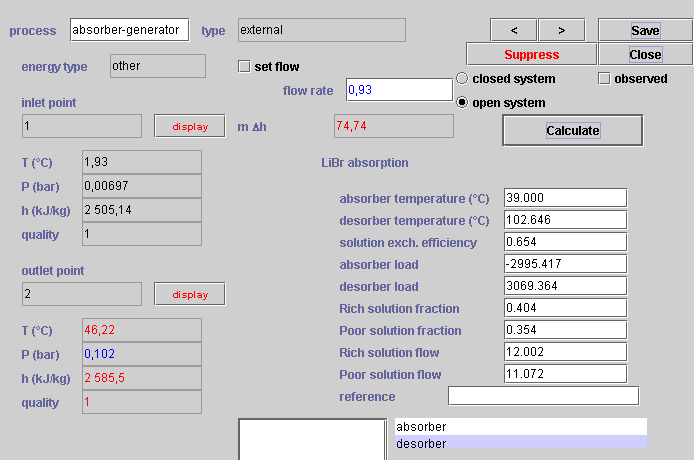

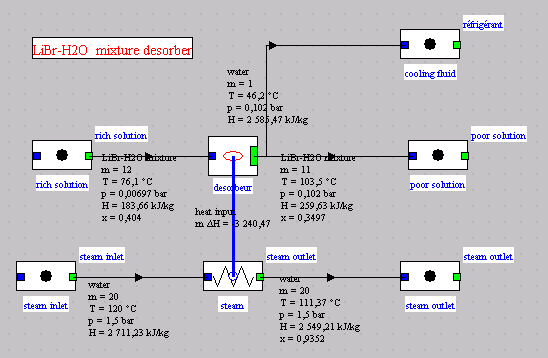

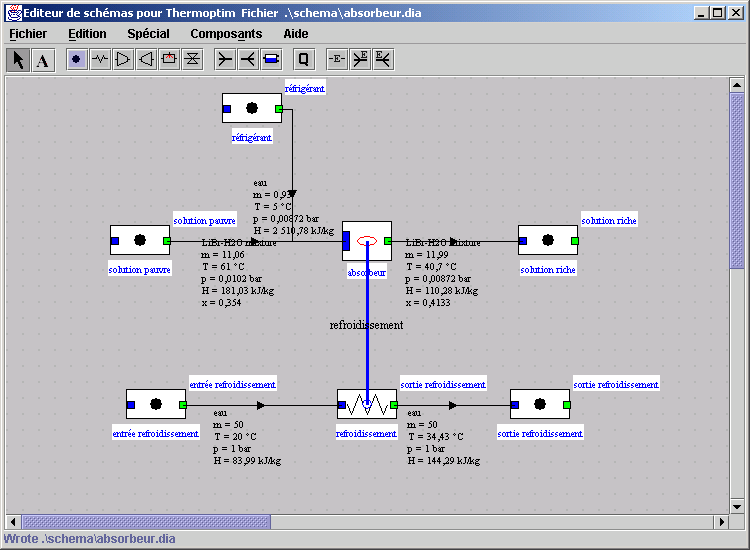

The figure above is an illustration of this: An absorption refrigeration cycle, whose absorption-desorption system is defined and integrated in an external process, is supplied with the steam that exits the evaporator then enters the condenser. This cycle involves the mixture LiBr-H2O, whose properties are modeled either directly in the external process, or in an external substance, and requires high temperature heat supply to the desorber and medium temperature heat removal from the absorber. The representation of these thermocouplers is possible thanks to the thermocoupler system: the external process calculates the thermal energies that must be exchanged, and the thermocoupler recalculates the corresponding “exchange” process, which updates its downstream point.

The types of thermocouplers used by an external component appear in the lower right hand corner of the screen. Double click on one of the types to open the screen of the corresponding thermocoupler.

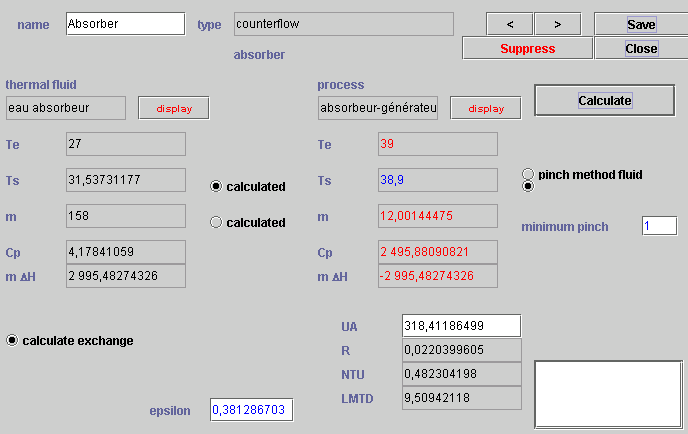

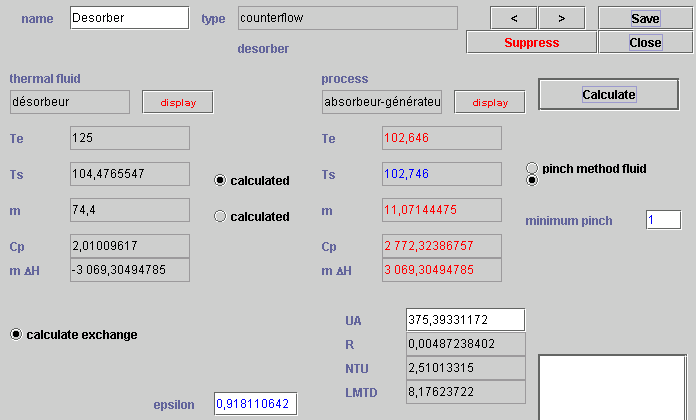

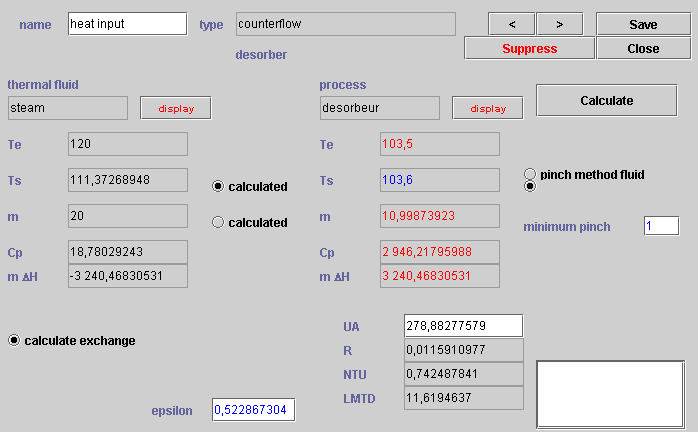

Given that thermocouplers are a type of heat exchanger, it is valuable to define them by values such as effectiveness ε, UA, NTU or LMTD, that can be calculated using similar equations. The component sends to each of its thermocouplers the equivalent values for flow rates, inlet and outlet temperature and thermal energy transferred, which they must take into account in their calculations. Specific methods are provided in the external class code and are not user-modifiable.

However, there are limits to the similarities with exchangers: for example, temperature crossovers unacceptable in an exchanger may occur in a thermocoupler, leading to absurd values.

So it is best to transmit values that are unlikely to lead to this type of situation. One possible solution is to assume that the thermocoupler is isothermal for calculations of characteristics that are similar to exchanger characteristics. For example, a combustion chamber may be assumed to be at mean temperature between its upstream and downstream points when calculating cooling. This assumption is not absurd and may prevent a temperature crossover between the cooling fluid and the gases that cross the component.

In the case of the absorption machine presented above, we assumed that the absorber and desorber were isothermal.

Both lead to the screens below. If we had not taken the temperature of the absorber as a reference for the exchange calculations, keeping the temperatures of the steam entering and exiting the external process, we would have ended up with a temperature crossover.

For external processes that accept several thermocouplers and for external nodes, the potential complexity of the calculations prevents the exchange process from driving the thermocoupler. Its load is always set by the external component. This is why there are fewer options for calculating a thermocoupler than for a heat exchanger: The user can only choose between calculating the outlet temperature of the exchange process (at a given flow rate) and the flow rate, when the temperature is known.

Note that on the thermocoupler screen, the external component fluid can be selected as a pinch fluid and a minimum pinch value can be entered (see optimization method, volume 1).

2.5.5 External Nodes

The nodes of Thermoptim basic set are extremely simple components used to complete the description of the fluid circuits. They are always adiabatic, and they ensure the conservation of the mass flow rate and enthalpy

However, there is one somewhat special component, considered as a process, but which is in fact a node in most cases: combustion, which receives an oxidizer and a fuel, and from which burned gases exit.

In the LiBr-H2O absorption example, a number of energy systems are involved, as well as components of varying complexity, which can have a number of input and outlet fluids, after various internal calculations, with or without thermocoupling with external heat sources.

External nodes allow a user to define these components. Only external mixers and dividers are defined: no component simultaneously performs both functions (receiving and emitting several fluids), but you need only couple an external mixer with an external diffuser to do so.

In many respects, we encounter the same problems in implementing these external nodes as with thermocouplers: the potential complexity of the calculations to be made in the node makes it necessary for the node to take over and control both the main vein and the branches, since no default calculation is possible.

The verification and consistency problems are even more critical than for thermocouplers: only the node designer knows which processes it must be connected to in inlet and outlet. The user must refer to the documentation of the class to know how to use it.

The figure above shows the diagram of a desorber for an absorption machine using the LiBr-H2O mixture whose properties must in this case be provided by an external substance.

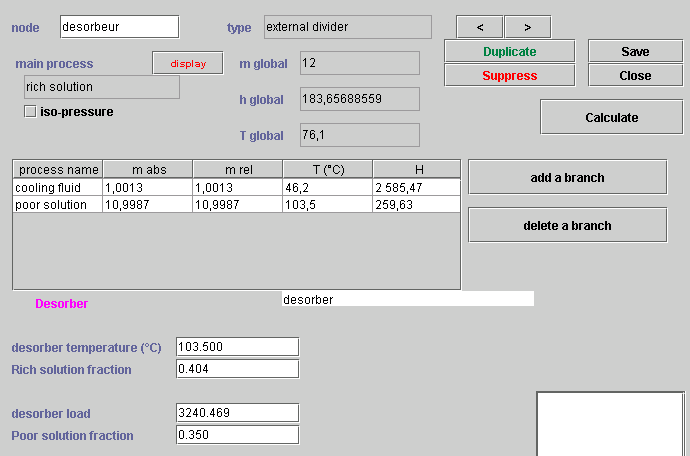

The external node screen is shown opposite. As with external processes, it contains a general part defined in the Thermoptim basic set, completed by a part defined by the user (here the lower left zone).

In the model shown here, the only parameter defined in the node is the temperature of the desorber. The properties of the rich solution (mass fraction and flow rate) and the state of the refrigerant are obtained from their respective processes.

The node calculates the flow rates of the refrigerant and the poor solution, its state, and heat supply required.

The thermocoupler then calculates the final state of the steam used.

Before each recalculation, the node checks that its structure is correct and loads the values that it needs to be calculated. Then it updates the thermocoupler that can in turn be recalculated. In this example, we assumed that the desorber was isothermal, and we took the flow rate of the poor solution as the reference flow rate.

2.5.6 Miscellaneous comments

You may have noticed that the screens of the external processes represented here are composed partly of Thermoptim internal code and partly of external code (lower right section in the processes, lower left in the nodes.). This is because the character strings used in the external components have not been “internationalized” the way the Thermoptim basic set has.

But this does not affect their use in any way. However, you can see that the number display has not been internationalized either, so the decimal separator is not the same: it is a period and not a comma. Of course, this can be modified, but it has not yet been done. This means that the figures must be entered with a point in the part defined in the external component, and with a comma in the rest of the screen. It is important to pay close attention to this issue, otherwise number formatting errors will be detected by Java.

2.6 Representation of real fluid mixtures in Thermoptim

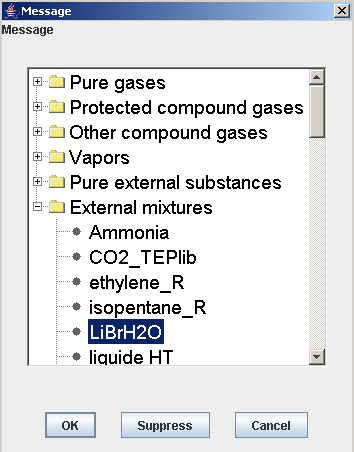

Until 2005, the only Thermoptim substances whose composition could be defined by the user were compound gases. It was impossible to represent real fluid mixtures. The external substance system was reworked to be able to do so, via the introduction of a new type of substance, called “external mixture”, and substances formerly known as external substances were renamed “pure external substances”.

An external mixture is made from a system, i.e. from a given set of pure substances, and its composition is specified in a new editor.

The distinctive characteristic of these external mixtures is that they can be used to generate a set of substances from the same system of pure substances. In this way, they are similar to compound gases. The difference is that the interactions among real fluids are much more complex than among ideal gases, so you must specify not only the pure substances used, but also their models, mixture rules and a number of additional parameters.

2.6.1 Link between Thermoptim and thermodynamic properties servers

The system makes it possible not only to define external mixtures by completely writing their external classes, but also to calculate those using thermodynamic properties servers (TPS), software packages that have specialized libraries, such as TEP ThermoSoft developed by the Centre Energétique et Procédés of Ecole des Mines de Paris and Simulis Thermodynamics made by ProSim.

This link is a very valuable extension of Thermoptim, since it means that many new fluids can be used in the software, with extremely accurate models. The trade-off is that it is somewhat complex and especially, calculation times can be long.

2.6.2 Creating an external mixture

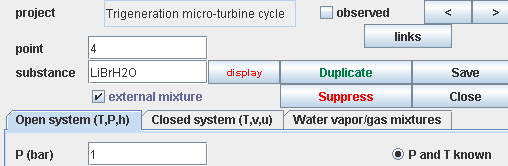

The point calculation screen has been modified slightly: an “external mixture” option has been added.

To create a new external mixture, select this option then enter a new substance name and press Enter.

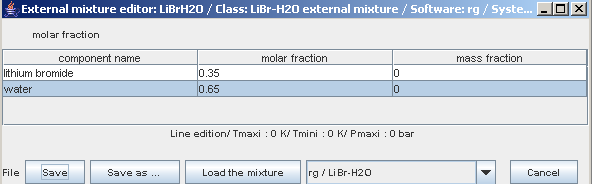

The external mixture editor can then be opened by clicking on “display”. By default, the external mixture created is of the type "LiBr-H2O external mixture" whose class is presented as an example in the programming documentation. If this is the desired substance, enter its composition, then click “Save”. The expected composition type (molar or mass fraction) is displayed above the component names column, and corresponds to the first column of figures from the left.

In the title of the external mixture editor the following items appear:

- the mixture name (here LiBrH2O)

- the corresponding external class identifier (here LiBr-H2O external mixture)

- the name of the software used (either a TPS, or as in this example (rg) a family of external classes).

- the system used (here LiBr-H2O)

This information is used to characterize the mixture by referring to the documentation. The same TPS may propose several systems, and may be used in several external classes.

From the pop-up menu located in the lower right of the editor screen you can display all of the systems available. If the one proposed by default is not the one you want, select one from the list and click “load the mixture”. The editor is then updated, and you can enter the composition and click “save”.

In a Thermoptim project file (.prj), the data for external mixtures are saved in the same way as for compound gases.

COMPOUND SUBSTANCES 2

Name of gas / Components molar fraction mass fraction

gaz_brulés 5

CO2 0.0309766336 0.0477375785

H2O 0.0619532671 0.0390824699

O2 0.14154164 0.158596897

N2 0.756807249 0.74238276

Ar 0.0087212103 0.0122002945

LiBrH2O 2 extMixture=true classe=LiBr-H2O external mixture syst=LiBr-H2O

lithium bromide 0.35 0

water 0.65 0

extMixture=true indicates that it is an external mixture, and the rest of the line specifies the class and the system selected. The next lines give the molar or mass compositions (for the time being, for a given mixture, the input can be done only in the manner selected by the designer of the external class, either in molar fractions, or in mass fractions).

Note that the order in which the components appears is not random: it is defined in the corresponding external class. Consequently, if you edit a project file manually, you must keep the same order for the system components.

The substance selection screen has been modified to distinguish between two categories of external substances. In this example, the three external mixtures on the bottom of the list correspond to different compositions of the same system.

Once the external mixture has been defined or loaded from the substance selection screen, its composition can be modified in the editor, and as we saw above, the system can also be changed by selecting one from the available libraries (pop-up menu on the lower right).

3 Programming external components

This section presents the basic notions needed to program external components, with some illustrations taken from the examples provided with the development environment. Once again, however, we would like to stress how important it is to properly prepare the documentation of your classes. The documentation must include at least two sections: the programming file and the user documentation. A poorly documented class will be difficult to use or modify, and the easiest time to document an external class is when it is created. Unfortunately experience has shown that this is only rarely the case…

Since the external class represents a component model that has a physical sense, it is important to write a note describing the model, both for the programming file and the user documentation. The code itself must include enough comments to make the links to the model as clear as possible (in particular it is best if the notations are uniform). Finally, the user documentation must specifically indicate the component constraints and requirements, with a thorough description of which inlet and outlet fluids can be connected to it, (name, nature, etc.) and how the thermocouplers, if any, must be constructed. The method getClassDescription () can be used to enter a brief description of the class, which can be consulted from a special Thermoptim screen. We recommend including the documentation references and the main constraints and requirements of the class in this method.

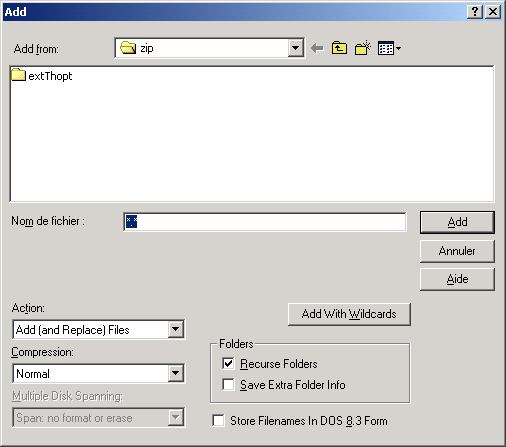

Practically speaking, you can proceed as follows: gather the following elements in an archive that has the same name as the class: the java code of the component, its class file, a modeling note, instructions for use with a short example of how it is used, and the .prj and .dia files for the example. A model library containing all of these archives can easily be created and updated.

3.1 External Substances

3.1.1 Construction of pure external substances

The structure of external classes was defined above. The class extThopt.CorpsExterne inherits from the rg.corps.CorpsExt class of Thermoptim and performs the interface, relaying the calculations to an abstract class (extThopt.ExtSubstance). This class defines the basic methods and is subclassed by the different classes introduced (for example extThopt.GlycolWater25, extThopt.GlycolWater40, etc.).é We recommend that you refer to the API of extThopt.CorpsExterne and extThopt.ExtSubstance to learn about the syntax and functions of all of the methods available. This API is part of the development environment of the external classes available.

Since Thermoptim knows only the external interface class extThopt.CorpsExterne and the abstract class extThopt.ExtSubstance, the instantiations can use only these two classes. The synchronization between the internal and external methods must be done carefully, but it is the only way to make sure that the classes used are working properly.

We will begin by explaining the construction procedure implemented in Thermoptim, then we will show how to create a new external class, by subclassing extThopt.ExtSubstance.

3.1.1.1 Construction of a pure external substance in Thermoptim

The construction procedure is as follows:

- the user selects an external substance from the list, which shows the index in the arrays of external classes loaded in Thermoptim.

- you load this class, which you transtype in ExtSubstance, and encapsulate in an Object.

Class c=(Class)rg.util.Util.substClasses[i];//load the class of the external substance

Constructor ct=c.getConstructor(null);//carefully instantiate it with its constructor without an argument.

extThopt.ExtSubstance ec=(extThopt.ExtSubstance)ct.newInstance(null);

Object ob=ec;//encapsulate it in an Object (otherwise the argument will not go through!)

corps=(Corps)new CorpsExterne(ob);//instantiate the external substance

which is done by the following constructor:

public CorpsExterne(Object obj){

subst=(ExtSubstance)obj;

setNom(subst.getType());

setComment(subst.chemForm);

initCorpsExt(subst.M, subst.PC, subst.TC, subst.VC, subst.Tmini, subst.Tmaxi,

subst.Pmini, subst.Pmaxi, subst.typeCorps);

}

3.1.1.2 Creating a pure external substance

To create an external substance, simply subclass extThopt.ExtSubstance. Let us take the example of the class DowThermA.

The constructor is as follows:

public DowThermA (){

super();

type=getType();//type of substance

M=166; PC=31.34; TC=752.15; //initializations (molar mass, critical pressure and temperatures)

Tmini=293.15; Tmaxi=523.15; //minimum and maximum temperatures of the substance definition

chemForm="(C6H5)2O (73.5% vol), (C6H5)2 (26.5% vol)"; //chemical composition of the substance

}

The method getType() sends the type of substance as it appears on the Thermoptim screens:

public String getType(){

return "Dowtherm A";

}

The method getClassDescription () can be used to enter a brief description of the class, which will appear in the external class viewer (see section 3.6). Provide a short explanation of the model, and if possible cross-reference to more detailed documentation.

public String getClassDescription(){

return "data from FLUIDFILE software by Dow Chemical\n\nauthor : R. Gicquel April 2003";

}

The methods for calculating the properties of the substance are presented later in the manual.

3.1.2 Calculations on the pure external substances

3.1.2.1 Principles of correspondence

For the calculations, the arguments are passed by the non-obfuscated methods. Please see Appendix 1 for details on existing methods.

For example, the enthalpy equation is inverted to solve for T in extThopt.CorpsExterne by:

public double getT_from_hP(double hv,double P){

return subst.getT_from_hP(hv,P);

}

The interface class rg.corps.CorpsExt ensures the correspondence between inv_hp_T (obfuscated) and getT_from_hP (non-obfuscated) :

public double inv_hp_T(double hv,double P){

return getT_from_hP(hv, P);

}

Thus, any time inv_hp_T by is called by a method internal to Thermoptim for an external substance, the call is relayed to getT_from_hP by rg.corps.CorpsExt.

Going in the other direction, rg.corps.Corps or rg.corps.CorpsExt contains the following method:

public double getT_from_hP(double hv,double P){

return inv_hp_T(hv, P);

}

When getT_from_hP is called by an external method for an internal substance, the call is relayed to inv_hp_T.

3.1.2.2 Examples of implementation

The class DowThermA defines a heat transfer fluid used in the exchangers. The substance remains in the liquid state at all times, and the calculations are simple: For example enthalpy, which is a function only of temperature (and its inversion).

public double calcH (double T, double P,double x) {

double a=0.00281914712153519,b=1.51937611940298;

double TT=T-273.15;

return b*TT+a/2.*TT*TT;

}

because h is given by a second degree polynomial to solve for T, its inversion is explicit:

public double getT_from_hP(double $hv,double $P){

double a=0.00281914712153519,b=1.51937611940298;

double c=-$hv;

a=a/2.;

double delta=b*b-4.*a*c;

double TT = (-b+Math.pow(delta,0.5))/2./a;

return TT+273.15;

}

The calculations here are very simple. If we were dealing with a condensable vapor, they would be much more complex. The class LiBrH2Omixture is a somewhat more complicated example.

3.1.3 Constructing external mixtures

3.1.3.1 Special issues

Like pure external substances, external mixtures are extThopt. ExtSubstance type, even if their calculations are performed in the TPS. To differentiate them, external mixtures must implement the interface extThopt.ExternalMixture, which specifies which methods they must define (see below).

The names of the pure external substances are listed on the substance selection screen, where they are used to instantiate classes.

For external mixtures, things are much more complex, because the same external class can define several systems, and each system generates as many compositions as the user wants, except of course if you are dealing with a pure substance, in which case the molar fraction and the mass fraction are both 1. Each external class defines all of the systems it proposes, and these systems cannot be modified by the user from within Thermoptim.

The class rg.corps.ExtMixture is used to instantiate the mixtures. It has a Substance called refExternalSubstance, which corresponds to the external class where the calculations are done, and with which it exchanges the system name and the selected compositions, using the method CorpsExterne (which must not be obfuscated, of course):

public void CalcPropCorps (double T, double p, double x, String systType, double[] fract_mol) {

//we start by updating the system composition

subst.updateComp(systType, fract_mol);

double U=20., H=10., S=0.5, V=0.01, Cv=0., Xh=0.;

if((T>=subst.Tmini)&&(T<=subst.Tmaxi)){

//we call the method CalcPropCorps of the external mixture

double[]val=subst.CalcPropCorps (T, p, x);

//we load the values calculated

H=val[0];

V=val[1];

Cv=val[2];

x=val[3];

U=val[4];

S=val[5];

}

else{

String message=resIntTh_fr.getString("mess_116");

JOptionPane.showMessageDialog(new JFrame(),message);

}

//update of the substance variables (hidden)

setState(p, T, x,//in arguments

U, H, S, V, Cv, Xh);//to be recalculated

}

This method relays the system selected (systType) and its molar or mass fraction (fract_mol) to the external substance (subst), then calculates the point.

In order to return the value of the vapor quality or the composition at liquid-vapor equilibrium, we defined the method getQuality(), which returns an array of doubles corresponding to the variable X of ExtSubstance, which must be correctly updated when inversion calculations are performed.

Any external mixture must return three methods defined in the interface extThopt.ExternalMixture, used to initialize ExtMixture when it is instantiated:

- public String getSoftware(), which defines the thermodynamic properties server used

- public Vector getMixtures(), which defines the names of the different systems, and the substances they contain

- public boolean isMolarFraction(), which is true if the composition must be entered in molar variables, and otherwise it is false.

The structure of the Vector vMixtures is as follows:

String[] system={"lithium bromide","water"};

vMixtures= new Vector();

Object[]obj=new Object[2];

obj[0]="LiBr-H2O";

obj[1]= system;

vMixtures.addElement(obj);

Note that isMolarFraction() serves only to define the mixture editor display: In all cases the composition transits via the array fract_mol.

3.1.3.2 Critical or pseudo-critical values: getCriticalParameters() method

Critical values of a mixture depend on its composition and cannot be initialized once and for all. To transfer them in Thermoptim the external mixture uses getCriticalParameters(), whose implementation for CTPLib (actually pseudo-critical values) is given by:

public double [] getCriticalParameters () {

double [] props = new double [4];

if (nbComponents == 1) {

props [0] = compProp [0] .TC;

props [1] = compProp [0] .PC / 1.e5;

props [2] = compProp [0] .VC;

props [3] = compProp [0] .M;

}dropoff window

else {

props [0] = CalcTcMix ();

props [1] = CalcPcMix () / 1.e5;

props [2] = CalcVcMix ();

props [3] = CalcMMix ();

}dropoff window

return props;

}

The values are transferred when the substance is calculated.

For an external mixture, the calculation of the state of the substance from Thermoptim is relayed to void rg.corps.ExtMixture.etat_complet (double TT, double pp, double x), which calculates from the class by:

refExternalSubstance.CalcPropCorps (TT, p, x, fractType, systType, fract_mol); // modRG 23/01

and then retrieves the values v = refExternalSubstance.getSubstProperties Vector ();

and updates all values, including the critical coordinates

When calculating refExternalSubstance.CalcPropCorps, critical values are determined by:

double [] getCriticalParameters prop = ();

subst.TC prop = [0];

subst.PC prop = [1];

subst.VC = prop [2];

subst.M = prop [3];

getCriticalParameters()returns the correct values.

3.1.3.3 Files associated with external mixtures

As in the case of compound gases, the list of external mixtures is saved in a file called "mel_ext.txt", which is updated each time a new mixture is created, and is used to initialize the substance selection screen.

external mixtures file

CO2_TEP TEPThermoSoft mixtures CO2 CO2;1.0;0.0

liqu pauvre TEPThermoSoft mixtures NH3-H2O ammonia;0.25;0.0 water;0.75;0.0

vap riche TEPThermoSoft mixtures NH3-H2O ammonia;0.75;0.0 water;0.25;0.0

mel pauvre TEPThermoSoft mixtures NH3-H2O ammonia;0.1;0.0 water;0.9;0.0

LiBrH2O LiBr-H2O external mixture LiBr-H2O lithium bromide;0.35;0.0 water;0.65;0.0

Fin

Fin

3.1.3.3 Example of external mixture: the system LiBr-H2O

The system provides a simple example of how to define an external mixture. Later in the manual we will give a more complex example on linking up with the Thermosoft TEP thermodynamic properties server, taking into account the characteristics of the ThermoSoft database. Another example is the coupling with the TEP Lib SPT which is detailed on the Thermoptim UNIT portal. As the latter is written in Java, the coupling is particularly simple.

Warning: this system is modeled in Thermoptim external classes in two ways: by the H2OLiBrMixture class as an external mixture, and by the LiBrH2OMixture class as a simple external substance. In the latter case, the mass fraction of LiBr X in the mixture uses the field usually devoted to the quality x.

In machines using the LiBr-H2O mixture, the difference in the vapor pressure between the solvent (LiBr) and the solute (H2O) is such that we can set aside the mass fraction of the solvent in the vapor phase, which simplifies the calculations. Note that it is common practice to define the parameters of the diagram of the LiBr-H2O mixture as a function of the mass concentration in solvent (LiBr) and not in solute. Since water is likely to crystallize at low temperatures, the mixture crystallization curve is often shown on the diagram, corresponding to a lower operating limit for the machines.

For this pair, the ASHRAE proposes equations (1) and (2), set up by generalizing the refrigerant (water) saturation pressure law to the mixture, in which the water temperature t' (°C) is replaced by a linear function of the solution temperature t (°C). P, expressed based on a decimal logarithm, is the pressure in kPa, and X is the mass fraction of the mixture in LiBr. These equations are valid in the following value intervals: -15 < t' < 110 °C, 5 < t < 175 °C, 45 < X < 70 %.

ASHRAE, Fundamentals Handbook (SI), Thermophysical properties of refrigerants, 2001

Table 1 coefficients of equations 1 and 2

| ASHRAE | 0 | 1 | 2 | 3 | 4 |

|---|---|---|---|---|---|

| A0 | -2.00755 | B0 | 124.937 | C | 7.05 |

| A1 | 0.16976 | B1 | -7.71649 | D | -1596.49 |

| A2 | -0.00313 | B2 | 0.152286 | E | -104095.5 |

| A3 | 0.0000198 | B3 | -0.000795 |

The constructor initializes the validity limits of the class and the Vector vMixtures, which in this case includes just one system:

public H2OLiBrMixture (){

super();

type=getType();

M=29;PC=10;TC=350; //Attention: initialisations without physical sense

Tmini=278.15; Tmaxi=448.15;

chemForm="LiBr-H2O mixture";

typeCorps=6;//external susbstance type isMixture

vMixtures= new Vector();

Object[]obj=new Object[2];

obj[0]="LiBr-H2O";

obj[1]=system;

vMixtures.addElement(obj);

}

String[] system={"lithium bromide","water"};

The following methods define the class description, the software used (since it is not a TPS, the name is not important in this case), the unit to be used to express the composition (in this case mass), the system proposed, and the identifier of the class.

public String getClassDescription(){

return "external mixture class\nWatch out! the LiBr composition is to be expressed as mass fractions";

}

public String getSoftware(){

return "rg";

}

public boolean isMolarFraction(){

return false;

}

public Vector getMixtures(){

return vMixtures;

}

public String getType(){

return "LiBr-H2O external mixture";

}

The composition is updated based on the following method, which uses the intermediate variable x, equal to X/100.

public void updateComp(String systType, double[] fract_mass){

//attention: x represents the mass fraction, even if it goes through fract_mol in ExtMixture

selectedSyst=systType;

x=fract_mass[0];

}

The other methods (not presented here) define the calculations to be performed to solve equations (1) and (2).

3.1.4 Instantiation from external classes

It is possible to directly instantiate an external mixture from the external classes, for example in a driver. The syntax is provided below. You simply have to indicate the system selected (here "LiBr-H2O"), and update the composition (particularly simple in this case). The calculation and inversion functions can then be used directly, and the results can be written in the output file, for example.

H2OLiBrMixture monCorps=new H2OLiBrMixture ();//instantiation of the substance

double[]fractmass={0.35,0.65};

monCorps.updateComp("LiBr-H2O",fractmass);

System.out.println("Enthalpie du mélange externe LiBr-H2O pour la composition massique : "+fractmass[0]+" LiBr");

for(int i=0;i<10;i++){

double T=280+10*i;

double[] val=monCorps.CalcPropCorps(T, 5, 0);

System.out.println("T :\t"+T+" h : \t"+val[0]);

}

which gives:

Enthalpy of the external misture LiBr-H2O for the mass composition: 0.35 LiBr

T : 280.0 h : -5.2873148226108775

T : 290.0 h : 21.108948694345447

T : 300.0 h : 47.56170686221427

T : 310.0 h : 74.07095968099561

T : 320.0 h : 100.63670715068943

T : 330.0 h : 127.25894927129576

T : 340.0 h : 153.9376860428146

T : 350.0 h : 180.67291746524594

T : 360.0 h : 207.46464353858977

T : 370.0 h : 234.3128642628461

3.1.5 Coupling class with the properties server TEP ThermoSoft

Coupling with a thermodynamic properties server (TPS) such as TEP ThermoSoft is much more complex, on the one hand because this TPS is composed of calculation modules that are separate from Thermoptim, and what’s more they are developed in another language, and on the other hand because the calculable thermodynamic systems can vary greatly from case to case. We will illustrate the procedure using the example of the class TEPThermoSoft.java.

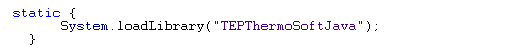

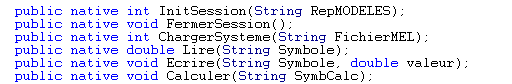

3.1.5.1 Interface between Java and Delphi

The following method is used to load the library "TEPThermoSoftJava.dll" which constitutes the interface with the Delphi environment in which TEP ThermoSoft was developed:

Next you must declare the Delphi methods callable from Java that serve to dialog between the two environments (please refer to Appendix 1 for details on their function and syntax)

3.1.5.2 Definition of mixtures proposed by the TPS

Each TPS should define a list of the systems proposed, which is placed in the “mixtures” folder of the installation directory. The standard format is as follows:

External mixture file

NH3-H2O NH3-H2O.mel 2 ammonia water M=44 PC=200 TC=404.128 Tmaxi=1100 Tmini=216.7 T0=293.15 P0=1.

CO2 CO2.mel 1 CO2 M=44 PC=73.77 TC=304.128 Tmaxi=1100 Tmini=216.7 T0=273.15 P0=36.59027

Fin

Fin

Each line contains:

- the name of the system as it appears on the Thermoptim selection screens (for example NH3-H2O)

- the mixture definition file, in the format of the properties server (for example NH3-H2O.mel)

- the number of components

- the name of the components as they appear on the Thermoptim selection screens

- the molar mass, the critical temperature and pressure, maximum and minimum temperatures for the fluid, and the reference temperature and pressure values (for which h=u=s=0)

It is basically via the mixture definition file that the properties server is initialized. Thermoptim simply modifies the composition and the state variables.

Note that this list contains the system “CO2” with just one component, i.e., a pure substance. The external mixture mechanism also makes it possible to emulate a TPS to represent a pure substance by a more precise model than the one used in Thermoptim. In this specific case, it is a dedicated equation that can be used in the neighborhood of the critical point.

Wagner, R. Span, A new equation of state for carbon dioxide covering the fluid region from the triple-point temperature to 1100 K at pressures up to 800 MPa. J. Phys. Chem. Ref. Data, 25(6):1509, 1996.

The arborescence of the properties server directories can be set up at the user’s discretion. The only requirements are that the dll links be placed in the installation directory and the list of systems proposed in the “mixtures” folder. In the case of TEP ThermoSoft, this list in contained in the file “TEPThSoft.mix”.

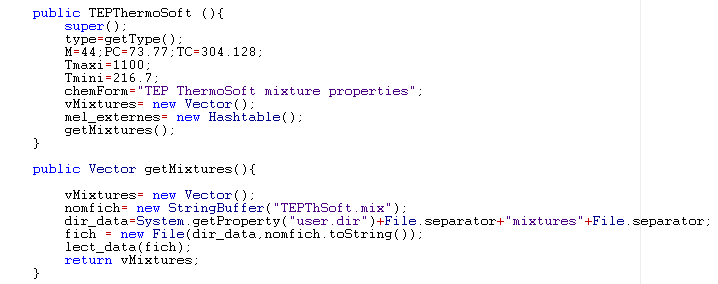

The constructor of the class TEPThermoSoft.java is very similar to the class considered above:

It introduces a Hashtable to be able to easily reference the existing external mixtures, and executes the method getMixtures() which constructs the Vector of existing mixtures and the Hashtable, by analyzing the mixture file "TEPThSoft.mix" using the method lect_data(). The same class can be used with various sets of mixtures depending on the applications.

The three methods of the ExternalMixture interface are then defined, which does not pose any particular problem.

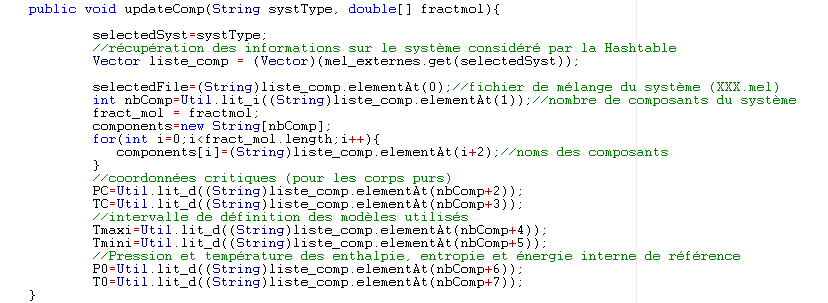

The method updateComp must be able both to initialize the system correctly and update its composition. To do so, it calls the Hashtable created by the constructor.

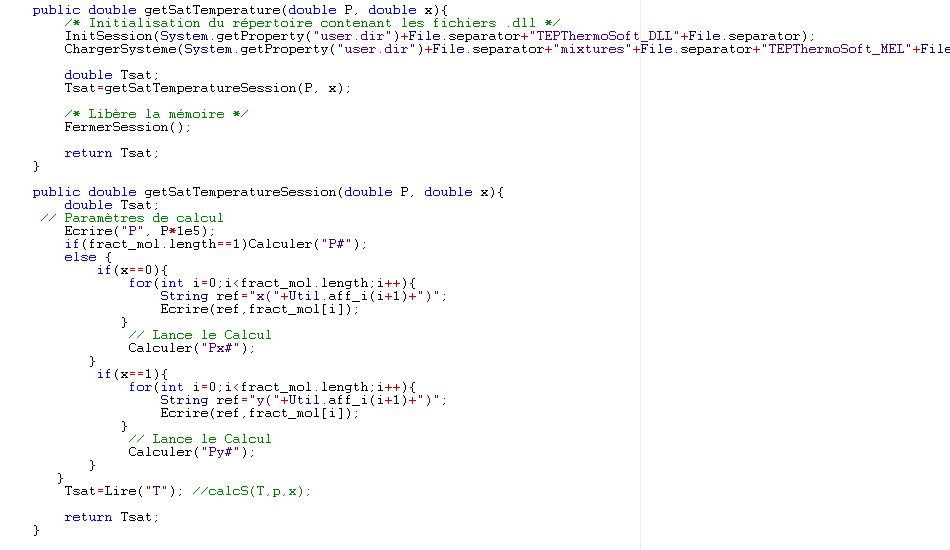

An example of how to calculate the saturation temperature is given below (bubble if x = 0, dew if x = 1). It provides a good illustration of the call sequence to the TEP ThermoSoft methods documented in Appendix 1. Schematically, we start by initializing the session and we load in the system in question, then we initialize the pressure, converted from bars to Pascals, and the composition of the mixture. Depending on whether it is a pure substance or a true mixture, the execution of the calculation differs slightly. The work session is closed to free up resources, and the saturation temperature is returned to Thermoptim.

In order to accelerate the calculations, it is better to avoid opening and closing a session whenever possible. Consequently, variants of certain methods utilizable only when a session is open have been implemented. They differ from the others in that the term Session is added to their name.

In both cases, we have created two sister methods: getSatTemperature() and getSatTemperatureSession(). The first manages the opening and closing of sessions, and second performs the calculations. This makes it possible to directly call the second without reinitializing the system.

The other calculation methods implemented are more complex, specifically those that use functions involving finding roots using the bisection method, but the principle is the same. We will refer to the comments documenting the class for additional information.

3.1.5.3 Inversion of functions

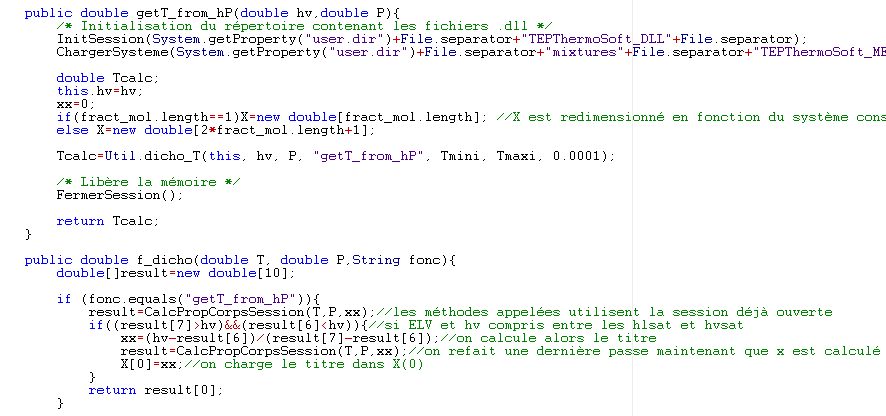

The example below is for the method inverting the enthalpy equation to solve for T, when pressure is known.

Overall the procedure is similar: Upon initialization, a session is opened, and the system is loaded. The inversion calculation can then be performed in this session, since the function f_dicho calls the version of CalcPropCorps that does not open its own session. When the calculations are done, the session is closed.

There is one particularity of this inversion method: during a liquid-vapor equilibrium, for a pure substance, the temperature determination is not enough. The vapor quality x must also be determined. It is calculated in f_dicho, then loaded in X[0], which Thermoptim can access using the method getQuality() of ExtSubstance.

For the time being, only the vapor quality of pure substances is used by the Thermoptim internal classes, but, as shown in the following section, the mechanism implemented in TEPThermoSoft.java is generic and allows the external classes to access the composition of multi-component mixtures.

3.1.5.4 Example of calculating the external mixture (NH3-H2O)

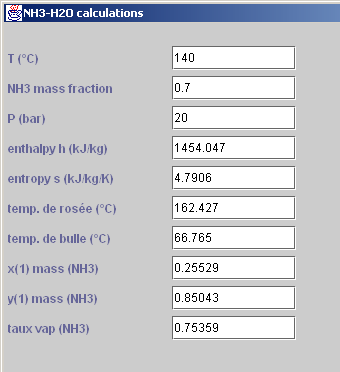

TEP ThermoSoft proposes the pair NH3-H2O as a mixture. In order to illustrate the calculations possible, we have created a small class called NH3_Absorption.java, which displays a screen of the principal properties useful for calculating absorption systems that use this mixture.

As usual for this application, the composition is entered in mass variables.

In the example opposite, at 140° C for a mass fraction of NH3 equal to 0.7, the point is located inside the isobaric lens at 20 bars, the bubble and dew temperatures are respectively 66.8 °C and 162.4 °C.

TEP ThermoSoft sends the liquid and vapor molar fractions of NH3, as well as the mean vaporization rate. Their values are sent by the array double[] X, which, in the case of a pure substance, contains only the vapor quality.

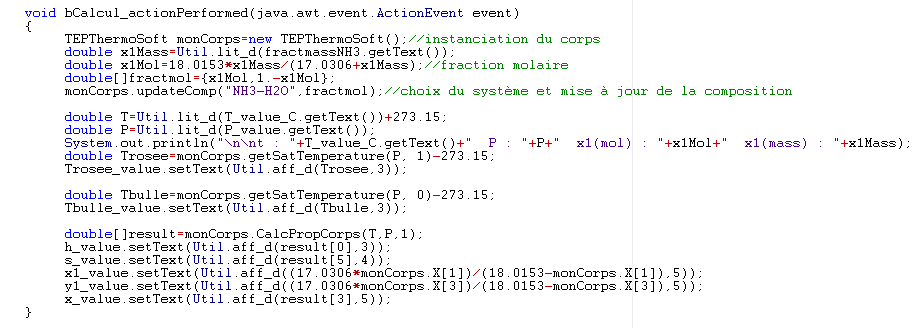

The code for performing the calculations in the class NH3_Absorption.java illustrates the use of the array X by an external class:

3.1.6 Thermodynamic charts of external mixtures

External mixtures not being included in Thermoptim, the software does not provide their thermodynamic charts. To overcome this limitation, we added a new chart type, called external mixture chart, which allows the use of simplified entropy and (h,P) charts.

The preparation of the chart background can be made thanks to a special external class called CreateMixtureCharts.java. You should refer to its documentation for further details on this topic.

The new charts are simplified compared to the others in that they show only the bubble and dew curves, as well as a single set of isovalues, i.e. the isobars for the entropy chart, and the isotherms for the (h, P) chart.

These charts being a variation of vapor charts, their use is explained in the documentation of these.

3.2 External Processes

The structure of external classes was defined earlier in this manual: The class extThopt.TransfExterne inherits from rg.corps.TransfoExt of Thermoptim and performs the interface, relaying the calculations at the level of an abstract class (extThopt.ExtProcess) defining the basic methods, and subclassed by the different classes introduced (for example extThopt.SolarCollector). We recommend that you refer to the API of extThopt.TransfExterne and extThopt. ExtProcess to learn the syntax and function of the methods available. This API is part of the development environment of the external classes available (in the folder api_extThopt).

We will begin by explaining the construction procedure implemented in Thermoptim, then we will show how to create a new external component, by subclassing extThopt. ExtProcess.

3.2.1 Construction

3.2.1.1 Construction of an external process in Thermoptim

The construction procedure is as follows:

- the user selects an external process from the list, which shows the index in the arrays of external classes loaded in Thermoptim.

- you load this class, which you transtype in ExtProcess, and encapsulate in an Object.

Class c=(Class)rg.util.Util.componentClasses[i];//you load the class of the external component

Constructor ct=c.getConstructor(null);//you carefully instantiate it with its constructor without an argument.

extThopt.ExtProcess ec=(extThopt.ExtProcess)ct.newInstance(null);

Object ob=ec;//you encapsulated it in an Object

- you then instantiate the class TransfExterne, which inherits from ComposantExt, i.e., it is in fact a JPanel containing the user interface defined in the external process.

JPanel1.remove(cType);

cType=new TransfExterne((Projet)Proj,ob, this);//we instantiate the external component

setupCType();//sets up the external user interface

which is done by the following constructor:

public TransfExterne(Projet proj, Object obj, TransfoExterne te){

this.proj=proj;

this.te=te;//we pass the ference to the TransfoExterne internal to Thermoptim

ep= (ExtProcess)obj;//retrieves the external class instantiated in TransfoExterne

ep.proj=proj;//retrieves the reference of the project

Vector vSetUp=new Vector();

vSetUp.addElement(te);//sends the reference to the TransfoExterne

vSetUp.addElement(ep.JPanel1);//loads the interface

vSetUp.addElement(ep.thermoCouplerTypes);//definition of the types of thermocouplers required

setUpFrame(vSetUp);//execution of setCompFrame();

ep.tfe=this;

}

- if the construction is done while the project file is being read, the process parameters are updated

- when a project is completely loaded, Thermoptim executes in each external component a special method called init() which performs initializations by referencing other instantiated external components (see section 3.4). This makes it possible to synchronize their methods.

3.2.1.2 Creating an external process

To create an external process, simply subclass extThopt.ExtProcess. Let us look at the example of the class SolarCollector (we have provided only part of the construction of the graphic interface here).

public SolarCollector (){

super();

JPanel1.setLayout(null);//Layout of the JPanel

JPanel1.setBounds(0,0,400,300);//dimensions of the JPanel (generally standard)

JLabel1.setText("glass transmittivity");//definition of the first label

JPanel1.add(JLabel1);

JLabel1.setBounds(0,0,164,24);

JPanel1.add(tau_value);//definition of the first editable text field for entering the glass transmittivity

tau_value.setBounds(164,0,124,24);

tau_value.setText("0.8");

type=getType();//type of process

thermoCouplerTypes=new String[0];//no thermocoupler connected

}

public String getType(){

return "solar collector";

}

public String getClassDescription(){

return "flat plate solar collector (without thermocoupler)\n\nauthor : R. Gicquel january 2003\n\nRef : note MODÉLISATION D'UN CAPTEUR SOLAIRE THERMIQUE";

}

3.2.2 Updating and calculating the process

Here we refer to the example of the class SolarCollector, whose model is presented in the note “SolarCollector.doc”

The sequence of operations is as follows:

- update the component before calculation by loading the values of the process and the upstream point

- read the parameters on the external component screen

- calculate the power used and the state of the downstream point

- calculate the thermal loads of the thermocouplers

- update the external component screen

Let us now look at the practical problems encountered during each of these steps. A few portions of the code are provided below, but we recommend reading the rest of this note while referring to the entire class SolarCollector.java.

1) update the component by loading the values of the process and the upstream point

The problem here is that an external component does not have direct access to the simulator variables: these values are obtained by very general methods, which construct Vectors with different structures depending on the desired object.

The procedure is not complicated, but it must be followed carefully:

String[] args=new String[2]; //array of arguments

args[0]="process";//type of element desired (a process in this case)

args[1]=tfe.getCompName();//name of the process (obtained by the reference tfe)

Vector vProp=proj.getProperties(args);//Project method given in Appendix 2

Double f=(Double)vProp.elementAt(3);

double flow=f.doubleValue();//flow rate value, automatically propagated from the upstream process

String amont=(String)vProp.elementAt(1);//name of the upstream point

getPointProperties(amont);//automatic decoding of the Vector (method of the ExtProcess class)

Tamont=Tpoint;//here T1

The method getPointProperties() of ExtProcess automatically loads the state of a point in easily manipulable values, called Tpoint, Point, lecorps… The method is given below.

public void getPointProperties(String nom){

String[] args=new String[2];

args[0]="point";//type of the element (see method getProperties(String[] args))

args[1]=nom;//name of the process (see method getProperties(String[] args))

Vector vProp=proj.getProperties(args);

lecorps=(Corps)vProp.elementAt(0);

nomCorps=(String)vProp.elementAt(1);

Double y=(Double)vProp.elementAt(2);

Tpoint=y.doubleValue();

y=(Double)vProp.elementAt(3);

Ppoint=y.doubleValue();

y=(Double)vProp.elementAt(4);

Xpoint=y.doubleValue();

y=(Double)vProp.elementAt(5);

Vpoint=y.doubleValue();

y=(Double)vProp.elementAt(6);

Upoint=y.doubleValue();

y=(Double)vProp.elementAt(7);

Hpoint=y.doubleValue();

y=(Double)vProp.elementAt(9);

DTsatpoint=y.doubleValue();

String dum=(String)vProp.elementAt(8);

isTsatSet=Util.lit_b(Util.extr_value(dum));

dum=(String)vProp.elementAt(10);

isPsatSet=Util.lit_b(Util.extr_value(dum));

}

- read the parameters on the external component screen

The package extThopt provides a number of simple but robust methods for converting the Strings displayed in the JTextField fields used on the graphic interface to doubles, and vice versa for displaying the doubles in these fields. They are implemented as static methods of the extThopt.Util class (see Appendix 3):

P=Util.lit_d(P_value.getText());

A=Util.lit_d(A_value.getText());

tau=Util.lit_d(tau_value.getText());

K=Util.lit_d(K_value.getText());

Tex=Util.lit_d(Tex_value.getText())+273.15;

- calculate the power used and the state of the downstream point

We begin by estimating the Cp of the heat-conducting fluid by making a limited development of the enthalpy function, which means we use the method CalcPropCorps() of the package Corps and the method getSubstProperties() of ExtProcess, which automatically loads the state of a point in easily manipulable values, called Tsubst, Psubst, etc. :

public void getSubstProperties(String nom){

String[] args=new String[2];

args[0]="subst";//type of the element (see method getProperties(String[] args))

args[1]=nom;//name of the process (see method getProperties(String[] args))

Vector vProp=proj.getProperties(args);

Double y=(Double)vProp.elementAt(0);

Tsubst=y.doubleValue();//temperature

y=(Double)vProp.elementAt(1);

Psubst=y.doubleValue();//pressure

y=(Double)vProp.elementAt(2);

Xsubst=y.doubleValue();//value

y=(Double)vProp.elementAt(3);

Vsubst=y.doubleValue();//mass volume

y=(Double)vProp.elementAt(4);

Usubst=y.doubleValue();//internal mass energy

y=(Double)vProp.elementAt(5);

Hsubst=y.doubleValue();//mass enthalpy

y=(Double)vProp.elementAt(6);

Ssubst=y.doubleValue();mass entropy

y=(Double)vProp.elementAt(7);

Msubst=y.doubleValue();//molar mass

Integer i=(Integer)vProp.elementAt(8);

typeSubst=i.intValue();//type of substance (1 for water, 2 for a vapor, 3 for a pure gas, 4 for a compound gas, 5 for an external substance)

y=(Double)vProp.elementAt(13);

ChemExerSubst=y.doubleValue();

}

Then we can calculate the Cp as follows:

double H=Hpoint;//enthalpy of the upstream point

lecorps.CalcPropCorps(Tpoint+1, Ppoint, Xpoint);// recalculates the upstream substance by a Thermoptim function

getSubstProperties(nomCorps);//retrieves the recalculation values (method of the ExtSubstance class)

double Cp=(Hsubst-H);//estimated value of Cp

We then calculate an estimated Taval value to be able to determine the absorbed thermal power Qex:

double DT0=tau*P/K-Tamont+Tex;

double T=Tamont+(DT0)*(1-Math.exp(-K*A/flow/Cp));

double DT=T-Tpoint;

double Qex=Cp*DT*flow;

We determine the value of the mass enthalpy of the downstream point, then we invert this equation to determine the exact value of Taval (method of the Corps class)

double hAval=Qex/flow+Hpoint;

Tpoint=lecorps.getT_from_hP(hAval,Ppoint);

getSubstProperties(nomCorps);//retrieves the recalculation values (method of the ExtProcess class)

Xpoint=Xsubst;//updates the value of the vapor quality in case the state is diphasic

- calculate the thermal loads of the thermocouplers

In this simple example, there is no problem, since the component does not use a thermocoupler. Brief instructions are given later in the manual, as well as in the section on external nodes.

- update the external component screen

The Thermoptim method setupPointAval() updates the downstream point from the values loaded in a Vector constructed here by the method getProperties() of ExtProcess:

tfe.setupPointAval(getProperties());

The solar collector yield value is then determined and displayed.

eff_value.setText(Util.aff_d(Qex/P/A, 4));

For this example, the updates before and after recalculation are very simple. In other cases, it may be necessary to access other data from the simulator. We will explain how to do this below.

3.2.3 Moist gas calculations

To perform the calculations for moist gases from external classes, the method getPointProperties() of ExtProcess retrieves the moist properties values of a point by the following variables:

Wpoint for the absolute humidity w, Epsipoint for relative humidity ε, Qprimepoint for specific enthalpy q', Tprimepoint for adiabatic temperature t' (in °C), Trpoint for dew point temperature tr (in °C), VPrimepoint for specific volume vs, Condpoint for condensates, and M_secpoint for the molar mass of the dry gas.

The method updatePoint given in the appendix forces the following moist calculations:

"setW and calculate all", sets w and calculates all of the moist properties

"setW and calculate q'", sets w and calculates all of the moist properties except t'

"setEpsi", which sets ε

"setEpsi and calculate", sets ε and calculates all of the moist properties

"calcWsat", calculates wsat and all of the moist properties except t'

"modHum", modifies the composition of the gas

3.2.4 Calculation of exergy balances

The external components can also be represented in a productive structure. Their exergy balance screen can be configured (using String [] getExergyType ()) by the constructor of the external class, for the time being to display, like that of "exchange" processes, three options and a value input field.

The choices made by the user are then transmitted to the external class for evaluation of getExergyBalance (String [] args), defined below; they are saved in the structure file. If additional settings are required, it is always possible to set them in the component's physical diagram screen.

Many exergy balance calculations of components pose no particular problem. It is however necessary to specify carefully how their different elements should be taken into account in the overall balance, as the system boundary is not same as that of a given component.

To calculate its exergy balance, each simulator component returns a double [] method getExergyBalance (String [] args) which includes the seven values to be taken into account in the overall balance (five ports plus exergetic efficiency and irreversibility).

For Thermoptim core elements, the rules for weighting the values of provided to the cycle can be fixed once and for all, but it is not the same for external components, for which the designer must always specify which values should be included in the overall exergy balance sheet.

The models of components that can be implemented are so diverse that it is not possible to predict all cases. This is why the external components refer, in addition to the previous seven values, to two coefficients ranging between 0 and 1 (tauPlusFactor and deltaXhPlusFactor) which allow one to weight the fraction of the useful work and positive heat exergy supplied to the cycle.

The ExtProcess class includes a default implementation of String [] getExergyType() and double [] getExergyBalance (String [] args), to be sub-classed by external components. The exergy fluid properties must be calculated from the values of enthalpy, entropy and T0 provided by getSubstProperties ().

The exchange of getExergyBalance between Thermoptim and the external components is done by public double [] getCompExergyBalance (String [] args).

For the calculation of exergy of incoming and outgoing flows, a reference value is taken for T0 and 1 bar.

In PointCorpsDemo, its implementation without argument is as follows:

// calculates the reference exergy, chemical exergy not to be accounted

public double getExergyReference (){//modRG oct04//modRG exerg

lecorps.CalcPropCorps(Util.T0Exer,1,1);

return lecorps.H-Util.T0Exer*lecorps.S;

}

In ExtProcess it is, with two arguments:

/**

- returns exergy reference value and initializes T0Exer

- /

public double getExergyReference(Corps corps,String nomCorps){

String[] args=new String[2];

args[0]="project";//type of the element (see method getProperties(String[] args))

args[1]="";//name of the process (see method getProperties(String[] args))

Vector vProp=proj.getProperties(args);

Double f=(Double)vProp.elementAt(2);

T0Exer=f.doubleValue();

corps.CalcPropCorps(T0Exer,1.0,0);

getSubstProperties(nomCorps);

return Hsubst-T0Exer*Ssubst;

}

Default implementations for the external components are given below:

The ExtProcess class includes a default implementation of getExergyType () and getExergyBalance (String [] args), to be sub-classed by external components. The fluid exergy properties are given by getSubstProperties ().

double tauPlus,deltaXhPlus,xqPlus,tauProduct,deltaXhProduct,etaExer,deltaXhi;

void setExergyExtensor(boolean isExtensor){

if(isExtensor)exergyType="extensor";

else exergyType="reductor";

}

public String[] getExergyType(){//modRG exerg

String[] type=new String[9];

type[0]=exergyType;//extensor or reductor

type[1]="false";//affiche JCheckExtSource

type[2]="External source";//label JCheckExtSource

type[3]="false";//affiche JCheckIntExchange

type[4]="Internal exchange";//label JCheckIntExchange

type[5]="false";//affiche JCheckValuableExergy

type[6]="Valuable exergy";//label JCheckValuableExergy

type[7]="false";//affiche champ d'entrée de valeur

type[8]="Source T (°C)";//label sourceT_value

return type;

}

public double[] getExergyBalance(String[]args){//modRG exerg

double[] exergyBalance=new double[9];

exergyBalance[0]=tauPlus;

exergyBalance[1]=deltaXhPlus;

exergyBalance[2]=xqPlus;

exergyBalance[3]=tauProduct;

exergyBalance[4]=deltaXhProduct;

exergyBalance[5]=etaExer;

exergyBalance[6]=deltaXhi;

exergyBalance[7]=tauPlusFactor;

exergyBalance[8]=deltaXhPlusFactor;

return exergyBalance;

}

3.2.4.1 Class SolarConcentratorCC

A solar panel converts the solar flux received in heat transmitted to the fluid flowing through it. This is therefore an exergy extensor, and in the SolarConcentratorCC class constructor, the type of UPD is set by setExergyExtensor (true);

The exergy calculations can be performed as follows:

double Xh0=getExergyReference(refrig);

tauPlus=0;

deltaXhPlus=0;

tauProduct=0;

xqPlus=P/1000*Sc*(1-T0Exer/5800);//le soleil est une source à 5800 K

deltaXhProduct=(Haval-Hamont-T0Exer*(Saval-Samont))*flow;

deltaXhi=xqPlus-deltaXhProduct;

etaExer=deltaXhProduct/xqPlus;

3.2.4.2 Class FluidEjector

An ejector is modeled as an external mixer. Depending on whether one is interested in motor or entrained flow, an exergy reductor or an exergy extensor. However, it may also simply be considered as a simple mixer, which avoids associating a junction or a branch.

To ensure that the incoming exergy is not considered as an external input to the cycle, the following two lines are inserted in the constructor:

deltaXhPlusFactor = 0;

tauPlusFactor = 0;

The exergy calculations can be performed as follows:

double Xhmi=Hmi-T0Exer*Smi-Xh0-getExergyReference(refrig,nomCorps);

double Xhmsi=Hsi-T0Exer*Ssi-Xh0-getExergyReference(refrig,nomCorps);

double Xhsr=Hd_is-T0Exer*Smix-Xh0-getExergyReference(refrig,nomCorps);

deltaXhProduct=msr*Xhsr;

deltaXhPlus=msi*Xhmsi+mi*Xhmi;

etaExer=deltaXhProduct/deltaXhPlus;

deltaXhi=deltaXhPlus-deltaXhProduct;

3.2.4.3 Class SOFCH2outlet

A fuel cell converts hydrogen into electricity. It behaves like a quadrupole receiving two input fluids, and out of which come the other two. The quadrupole is formed by combining an input mixer and an output divider, the two being connected by a process-point which plays a passive role. The calculations are performed by the output divider.

The exergy calculations can be performed as follows:

double DH0=-241830;//kJ/kmol H2 vapeur

double DH0_vap=-285830;//kJ/kmol H2 liquide

double DG0=-237160;//kJ/kmol H2

double elecPower=tau*DG0*epsi*molFlowH2;

double Qlib=-tau*DH0*molFlowH2+elecPower;

tauProduct=-elecPower;

etaExer=elecPower/DH0/molFlowH2;

deltaXhi=(1-etaExer)*tauProduct;

3.2.5 Managing Energy Types

It may first be necessary to manage the assignment of energy types in a more complex manner than in the processes of Thermoptim’s basic set, which are basically mono-functional. For the processes, the energies used are either purchased, useful, or other. In an external process, things may be different, with for example a thermal load in purchased energy and a power in useful energy.

The method updateProcess() of ComposantExt assigns the desired values to the different types of energy. It is easily used with the method setEnergyTypes of ExtThopt:

tfe.updateProcess(setEnergyTypes(tfe.getCompName(),useful,purchased,other));

public Vector setEnergyTypes(String process, double useful,double purchased, double other){

Vector vEner=new Vector();

vEner.addElement(process);//process name

vEner.addElement(new Double(useful));//useful energy

vEner.addElement(new Double(purchased));//purchased energy

vEner.addElement(new Double(other));//other energy

return vEner;

}

3.2.5 Access to other elements of the simulator

Access to upstream and downstream processes

The names of the upstream and downstream processes are accessible by the elements 9 and 10 of the Properties Vector of the external process.

String[] args=new String[2];

args[0]="process";//type of the element (see method getProperties(String[] args))

args[1]=tfe.getCompName();//name of the process (see method getProperties(String[] args))

Vector vProp=proj.getProperties(args);

String transfoAmont=(String)vProp.elementAt(9);//name of the upstream process (or "null" if none)

String transfoAval=(String)vProp.elementAt(10);//name of the downstream process (or "null" if none)

Once the name has been obtained, we access its properties by sending it to args[1] in proj.getProperties(args). In this way we can recursively run through the upstream and downstream processes directly connected to a process.

This is the mechanism used to update the processes upstream and downstream of the external nodes in the method public void updateStraightlyConnectedProcess(String startProcess, String name, boolean downstream, boolean inletPoint, boolean outletPoint, boolean updateT, double T, boolean updateP, double P, boolean updateX, double x) of ExtNode.

The example provided in the note “CycleLiBrH2O.doc” that is partially reprinted as an illustration of external nodes shows how to use these mechanisms.

Let us note in passing that vProp=proj.getProperties(args) also gives access to certain global properties of the project if args[0]="project" (see Appendix 2), and specifically the flow unit. This is a way to verify that the flow and power units implicitly or explicitly used in the external class are compatible with those of the project, and to send a message otherwise.

Thermocouplers

Given that thermocouplers are a type of heat exchanger, it is valuable to define them by values such as effectiveness ε, UA, NTU or LMTD, that can be calculated using similar equations.

The external component must send to each of its thermocouplers the equivalent values for flow rates, inlet and outlet temperature and thermal energy transferred, which they must take into account in their calculations. Specific methods were placed in the interface for this purpose.

However, the analogy with exchanges has certain limits: for example, temperature crossovers unacceptable in an exchanger may occur in a thermocoupler, leading to absurd values.

So it is best to transmit values that are unlikely to lead to this type of situation. One possible solution is to assume that the thermocoupler is isothermal for calculations of characteristics that are similar to exchanger characteristics, as in the model selected from the absorber and the desorber in the example presented in the note "TrigenMicroTAG.doc".

To be able to accept multiple couplings, all the heatConnectable define an array of acceptable thermocoupler types (in the example above: String[]thermoCouplerTypes={"absorber","desorber"}). The calls are then done using the type of thermocoupler as the identifier, as in:

public double getInletTemperature(String thermoCouplerType);

When the array has dimension 1 and the heatConnectable is a process, the management can be simplified (see below). Otherwise, the heatConnectable has to be able to distinguish which thermocoupler is calling it, in order to know what to send it back by the interface methods. It must therefore register with each thermocoupler when the thermocoupler is created. This assumes that a consistency check is performed during the initial construction, and this check must be repeated for each subsequent reconstruction.

For any external component there are also additional difficulties, given that its access to internal values is limited (the cases mentioned here are relative to process, but the problems also arise for nodes):

- the dimension of the array of acceptable thermocoupler types and those that are associated to it is not necessarily known, which means it must be initialized specifically in the method setCompFrame(Object obj) of ComposantExt, which is the pivot class where a large part of the exchanges between the internal part of the code and the external components are performed.

- the thermocoupler updates are done by the non-obfuscated method of TransfoExterne updateThermoCouplers(Vector vTC)

- the exchanges of information between the heatConnectable and its thermocouplers pass through Vectors, and it must be able to distinguish the different values depending on the role of each thermocoupler.

The method updateThermoCoupler() of ExtProcess performs the updates:

updateThermoCoupler(String type, double Tin, double Tout, double Q, double flow)

It sends the update elements to the thermocoupler via a Vector constructed by the methods of the ExtProcess class:

protected Vector getThermoCouplerVector(String type, double Tin, double Tout, double Q, double flow){

Vector vTC=new Vector();

vTC.addElement(type);

Double d=new Double(Tin);

vTC.addElement(d);

d=new Double(Tout);

vTC.addElement(d);

d=new Double(Q);

vTC.addElement(d);

d=new Double(flow);

vTC.addElement(d);

return vTC;

}

Though it is not recommended, we can avoid using the method updateThermoCoupler() for a simple external process, with just one thermocoupler and for which the inlet and outlet temperatures, thermal load and flow rate values can be directly obtained from the values of the process. However, if there are more than one thermocouplers connected to the same process, each one must be updated after each recalculation.

Note that a thermocoupler can be initialized only by the external component that it depends on. When a project is loaded, the state of the thermocouplers is updated only when the external components are calculated. To avoid problems during the first automatic recalculation of a project, we recommend performing a calculation of the external components equipped with thermocouplers using the method init() (see section 3.2.1.1).

Nodes

To identify the nodes to which a process can be connected, it is necessary to get the project nodes using the method proj.getNodeList(), retrieve the structure of each one by calling proj.getProperties() with the right arguments, and see if the name of the process appears among the names of the branches or the main process of the node. It’s a bit laborious, but even from within Thermoptim, this is how it has to be done.

Accessing the diagram editor