Presentation of the exercise

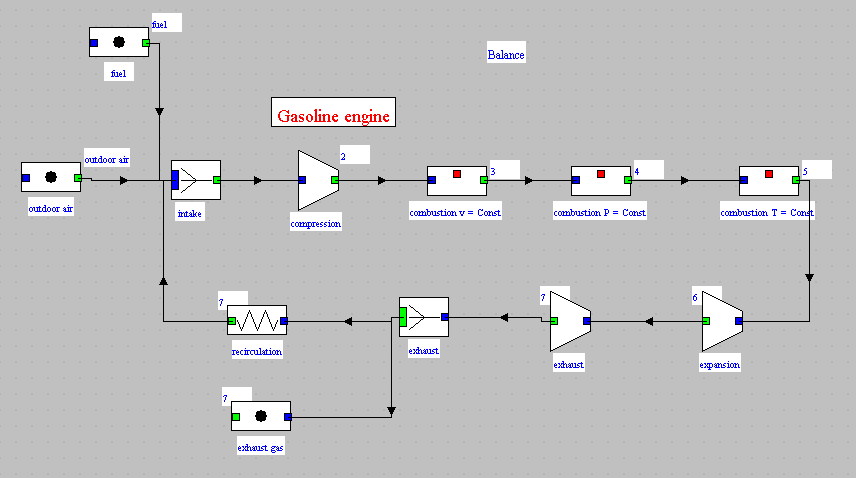

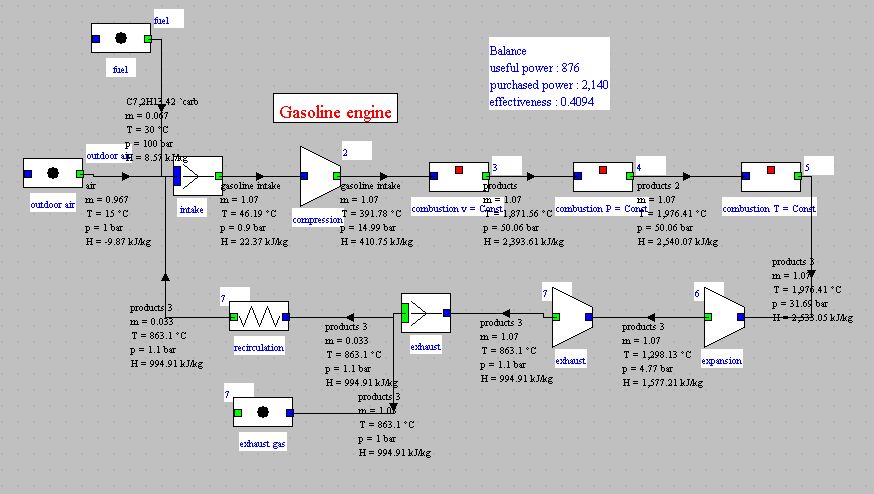

In this exercise, we study a gasoline engine represented by a theoretical associated cycle involving a non-adiabatic combustion in three stages: constant volume, constant pressure, constant temperature, and following the evolution of the thermodynamic properties of the fluid [THELLIEZ, 1989].

The diesel engine burns 67 g of fuel (pure gas of formula C7,2H13,42) per kg of combustion air. Its maximum pressure is 50 bar, and its maximum temperature 2250 K.

We take into account a gas recirculation rate of 3.3% by weight. Heat loss through the walls of the combustion chamber is 19%.

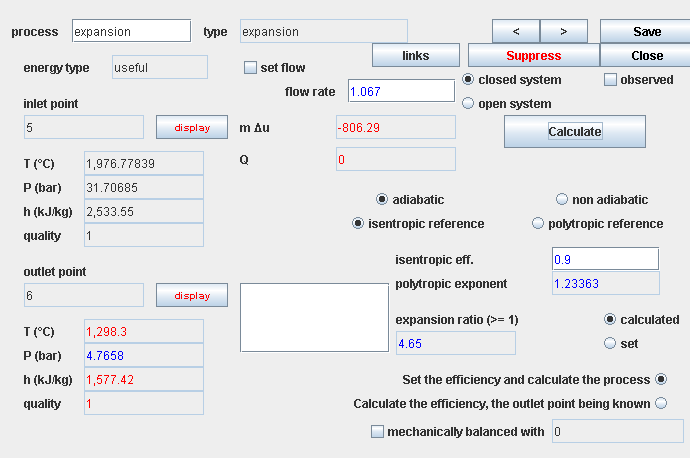

Isentropic compression and expansion efficiencies are equal to 0.9.

The model parameter settings are detailed in a note which can be downloaded from the link below. In the steps that follow, we present the main points. The numerical values given orally differ slightly from those of this note, initial values being not quite the same.

Publication reference:

M. THELLIEZ, Analyse énergétique des cycles des moteurs à combustion interne au moyen d’un cycle théorique associé, Entropie, 1989, n° 148, pp. 41-49.

If you are not familiar with the operation of reciprocal combustion engines, you should start by studying session S35En_4t2t.

To follow the presentation, go to the next step

(Session realized on 06/21/11 by Renaud Gicquel)Gasoline engine model

Definition of substances

- Inlets

- outdoor air

- fuel

- Mixer

- intake

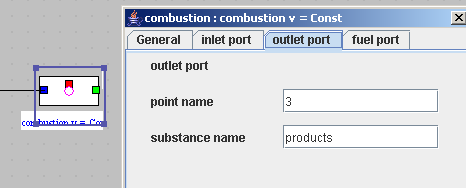

- Outlets of combustion chambers

- products 1, 2 and 3

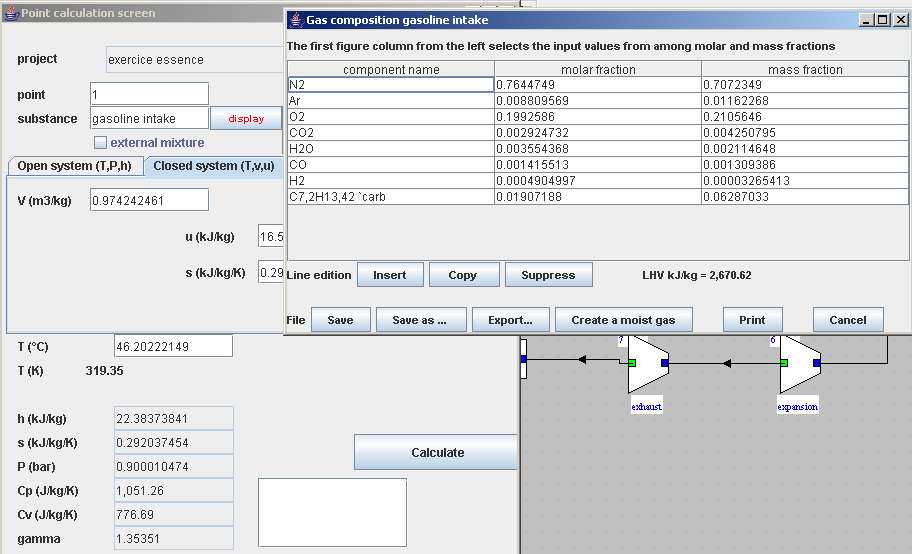

Gas composition display

Definition of the substance at the combustion chamber outlet

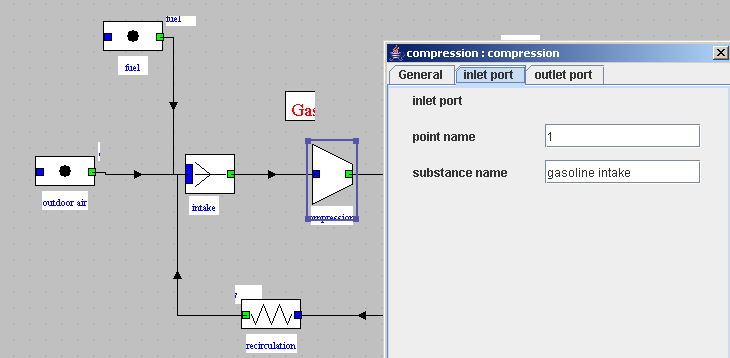

Definition of the substance at the mixer outlet

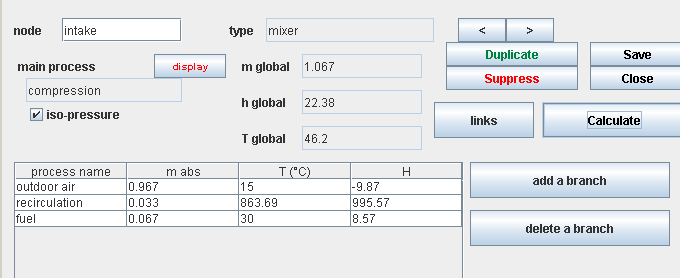

Intake mixer setting

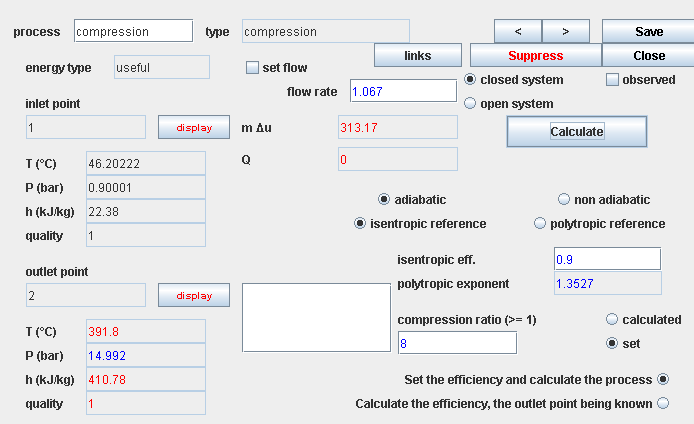

Closed system compression

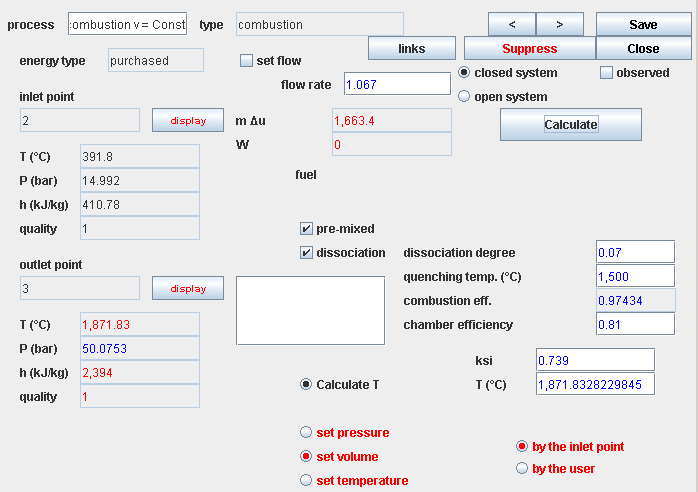

Constant volume combustion

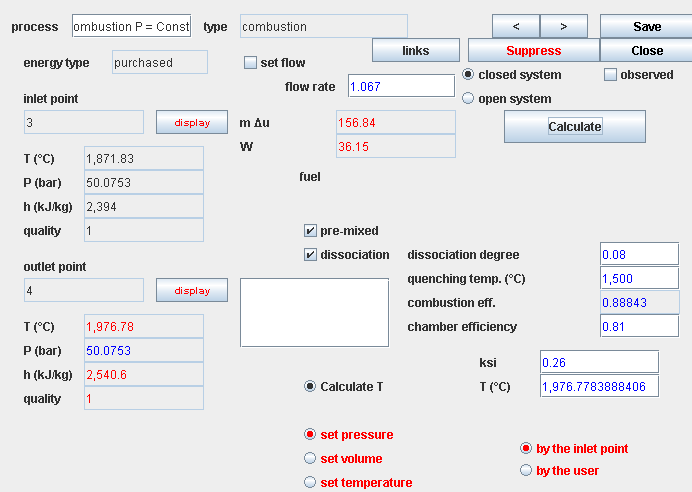

Constant pressure combustion

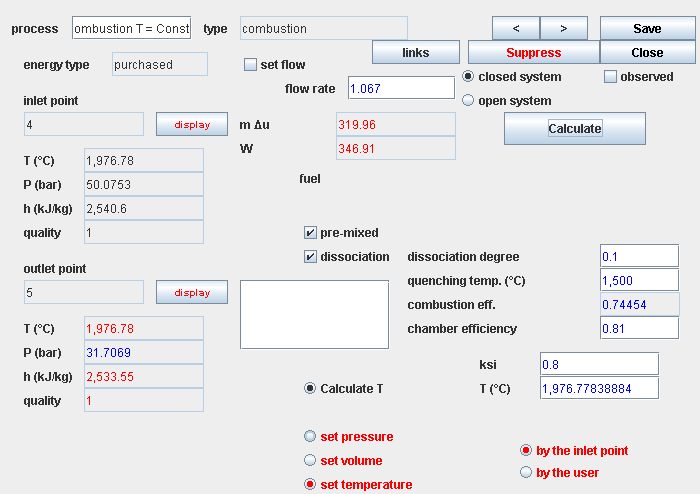

Constant temperature combustion

Closed system expansion

Synoptic view of the model

Summary

This exercise allowed you to study a gasoline engine by representing it a combined cycle, taking into account a mixed combustion in three stages, and following the evolution of the thermodynamic properties of the fluid, as presented in the session S36.

Such a model is much more realistic than those based on conventional theoretical cycles, but the downside is that its setting is a bit difficult, especially for all changes that take place in closed system.

It should be noted that the recalculation cannot be fully automated here. The reason is that the combustion in the motor cylinder is represented as a sequence of three closed system combustions: first constant volume, second constant pressure and third constant temperature. Since the setting of combustion is very specific, some adjustments must be made by hand, as for instance the setting of the burnt fraction of the reactants ξ to get the right pressure or proper final temperature or the update of v6.