Presentation of the exercise

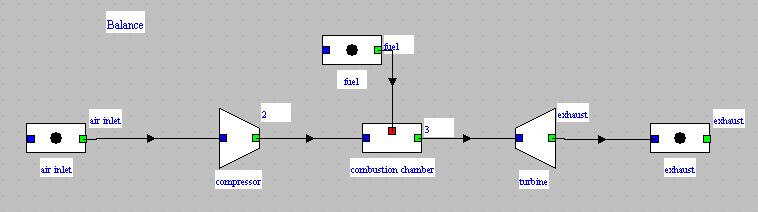

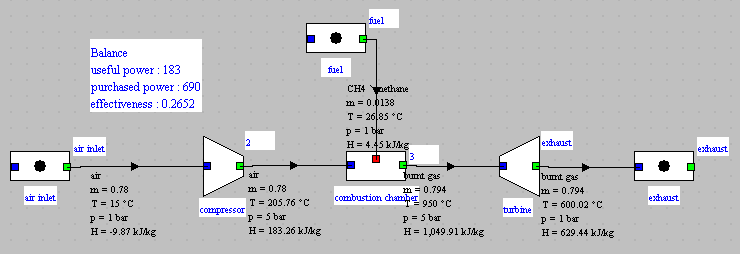

This exercise illustrates how to model with Thermoptim a small capacity gas turbine, called micro-turbine. This micro-turbine is an existing machine, used for several applications, including cogeneration.

In session S46En we will give a cogeneration facility example based on this machine.

This exercise combines more concisely those of sessions S21En and S22En, where the construction of the model was progressive, with a first model (S21En), in which it was assumed that the machine was traversed by a single gas, air, initially modeled as a perfect gas, and then a second model (session S22En), which took into account the combustion reaction that takes place in industrial machinery.

Before starting working with Thermoptim, we strongly recommend that you study session S07En_init, which introduces all the concepts which you will be using.

(Session realized on 06/16/11 by Renaud Gicquel)GT exercise

- gas turbine

- inlet conditions: 15 °C, 1 bar

- intake air flow: 0.78 kg/s

- compression ratio: 5

- compression isentropic efficiency: 0.875

- turbine inlet temperature: 950 °C

- expansion isentropic efficiency: 0.885

- fuel CH4 `methane

Thermoptim

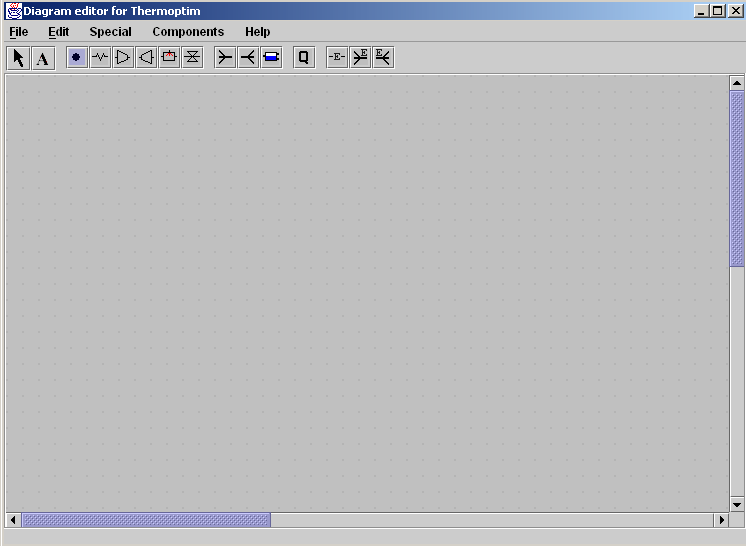

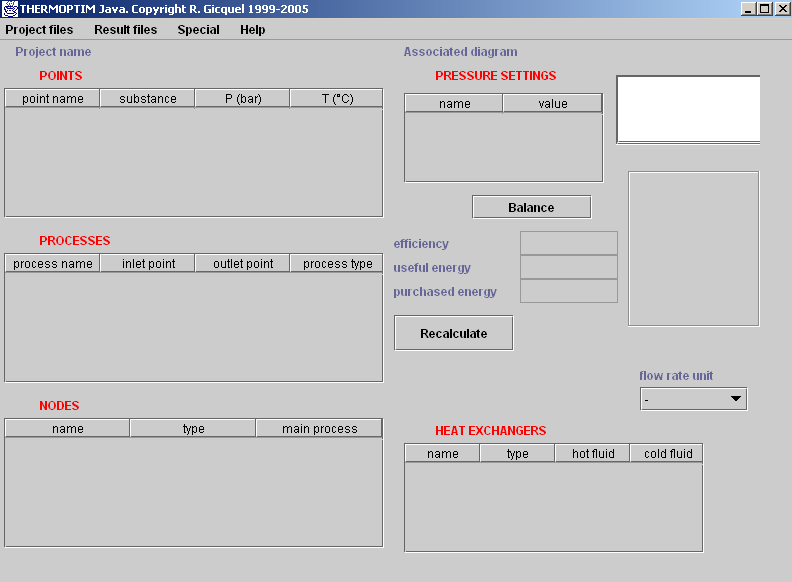

- two screens at opening

- diagram editor

- simulator

Thermoptim

Thermoptim

Thermoptim

Thermoptim

Thermoptim

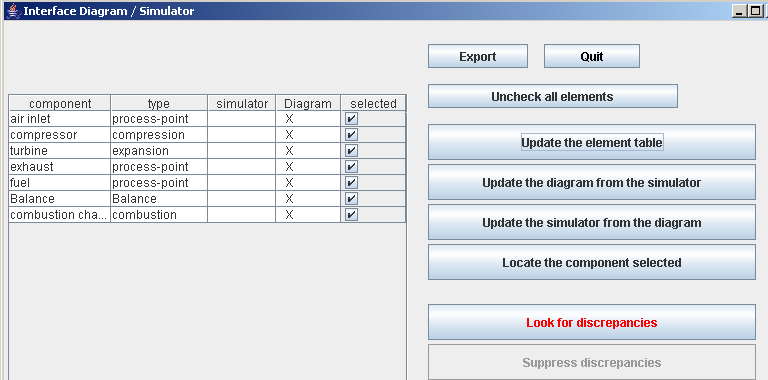

- diagram simulator interface

Thermoptim

Setting model parameters

When the simulator elements are created, Thermoptim initializes all the points with a pressure of 1 bar and a temperature of 300 K, which must then be modified according to the data of the problem you are studying.

The two steps that follow will show you how to set points and processes, then the next will remind you of the values that you should enter in Thermoptim.

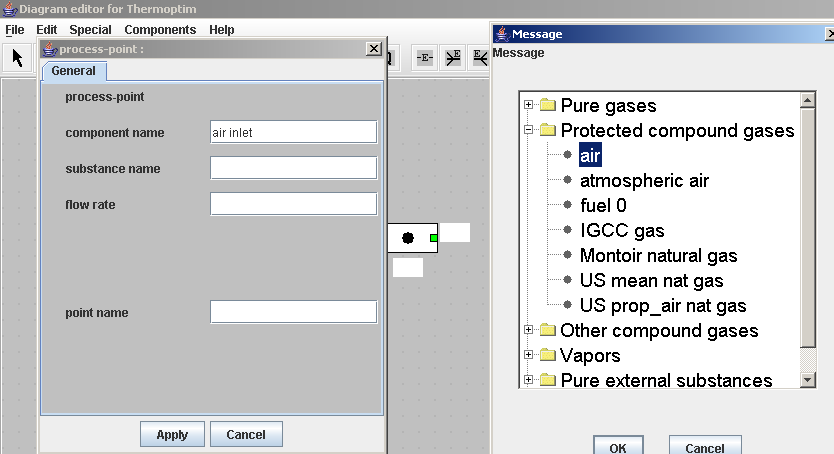

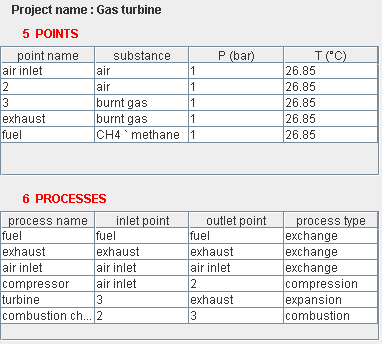

Point settings

- double-click on a link (arrow) on a line of the point table

- thermodynamic state of a small volume of matter

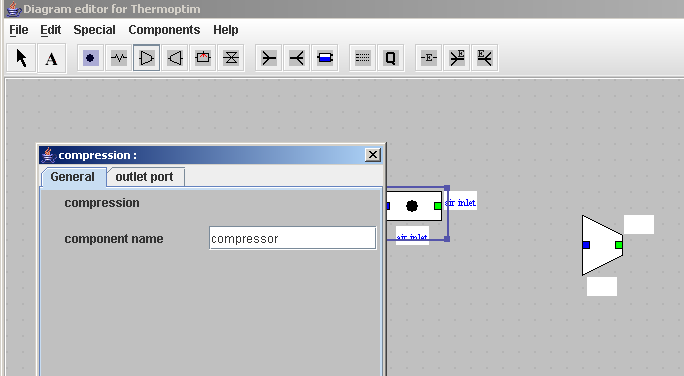

Setting processes

- double-click on a component or on a process table line

- fluid mass flow-rate

Setting the parameters of points and processes

Set now the parameters of the various points one by one, checking that you enter the values of the temperatures known (T1, T3), as well as those of the pressures, as Thermoptim does not set them automatically. In order to do that, follow these steps:

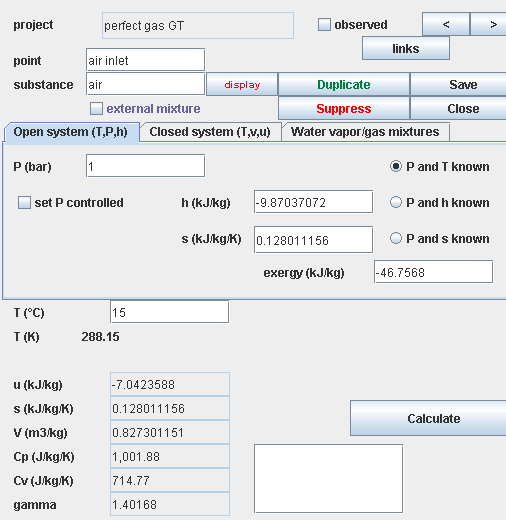

- open point point 1, enter a temperature of 15 °C and a pressure 1bar, then click on “Calculate”

- then open point 2, enter a pressure of 5 bar, and click on “Calculate”

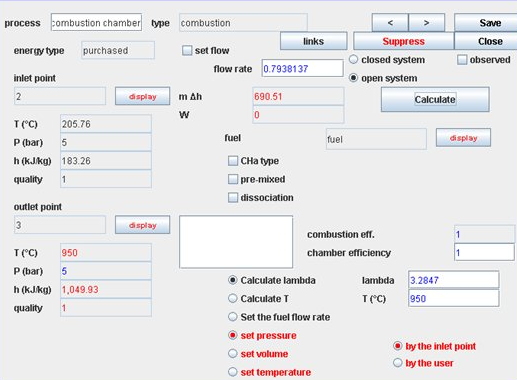

- open point 3 and enter a temperature of 950 °C and a pressure of 5 bar, and calculate it

It is not necessary to reset the point 4, since its pressure is 1 bar default and that its temperature will be recalculated later.

Set then the process’s parameters, for which default options are valid : the compression and the expansion are adiabatic, calculated with the isentropic reference, and their isentropic efficiencies are known. In order to do that, follow these steps:

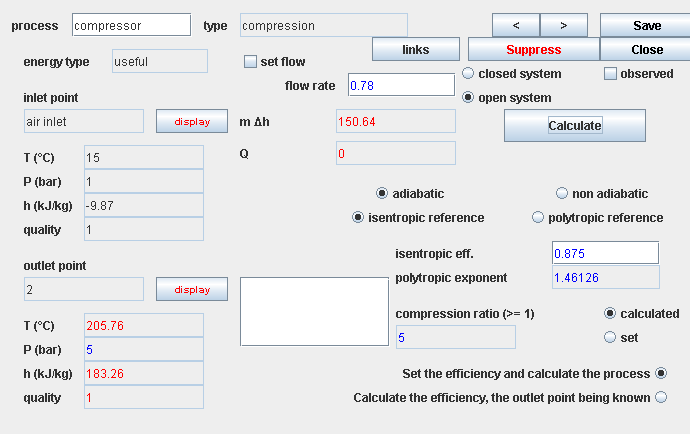

- open process “compressor”, and enter an isentropic efficiency of 0.875, then click on “Calculate”, which sets the temperature of point 2 (207.14 °C)

- setting the combustion chamber is explained in the next step

- open process “turbine”, and enter an isentropic efficiency of 0.885, then click on “Calculate”, which determines the temperature of point 4 (600 °C)

Each process has a type of energy that distinguishes “purchased”, “useful” and “other” energies, to determine the overall balance. For a gas turbine, the purchased energy is the energy supplied to the combustion chamber, and the useful energy the difference between the energy produced by the turbine and the energy consumed by the compressor.

As Thermoptim compression and expansion processes are of the “useful energy” type and the combustion chambers of “purchased energy” type, the default setting is appropriate here.

Thermoptim

Thermoptim

Comparison with the ideal gas model

This session enabled you to build a realistic model of gas turbine, taking into account the combustion reaction.

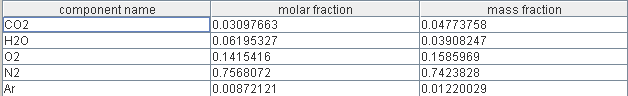

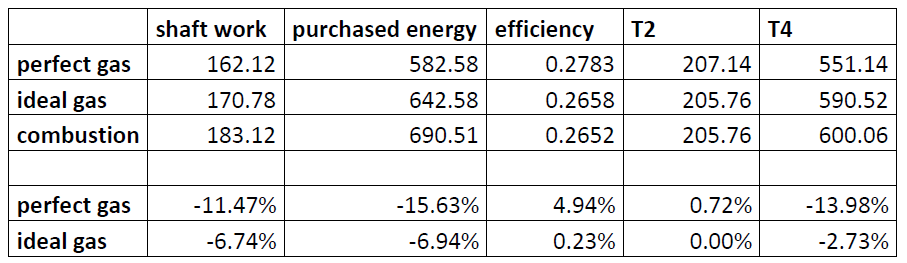

You can now compare the results with the previous model (session S21En), where we assumed that the machine was traversed by air, without change in composition. The following table summarizes the results:

- in terms of net mechanical power, the error of the perfect gas model (PG) is 11.5% and that of the ideal gas model (IG) 6.7% compared to the model with combustion (C)

- in terms of thermal power provided to the cycle, they are respectively 15.6% and 6, 9%

- errors on the efficiency remains low, however

- the errors on temperature differences in the compressor are much lower than in the turbine, where they reach high values (14% for the PG model)

In conclusion, even if the model (IG) is not too wrong, as we dispose of a modeling environment as Thermoptim, it is preferable to build a model as accurate as possible: it is no more difficult and there is no error.

Thermoptim project and diagram files are provided in the attached archive.

Review the summary of session 21En to remember the importance of looking critically at the results provided by a software package, and possibly refer to the note entitled “Model construction and verification methodology” (see link below).